SCANOLOGY 3D Model in Mold Industry

I modelli 3D semplificano il processo di progettazione, riducendo i tempi e i costi associati allo sviluppo degli stampi. La scansione 3D SCANOLOGY aiuta a identificare e correggere eventuali discrepanze o difetti negli stampi, garantendone il rispetto di rigorosi standard qualitativi. Supporta inoltre il reverse engineering, consentendo la ricostruzione di stampi sulla base di componenti esistenti. Infine, la scansione 3D nel settore degli stampi agevola la manutenzione e le riparazioni fornendo un riferimento dettagliato per il ripristino degli stampi.

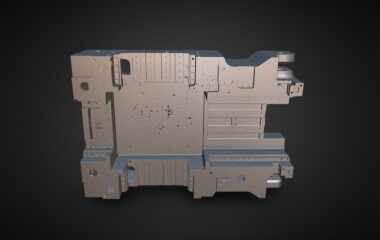

By using the SCANOLOGY KSCAN-Magic 3D scanner to create a 3D model of die casting mold, engineers can achieve high precision in replication, optimization, and prototyping.

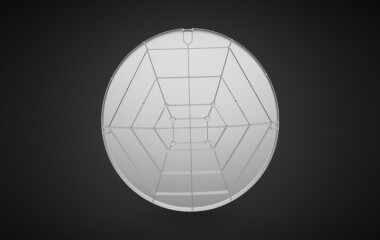

Using the SCANOLOGY SIMSCAN handheld 3D scanner for antenna mold measurement can enhance efficiency, accuracy, and overall quality in the antenna manufacturing process.

By creating and using the 3D model of stamping die, engineers can design, change, and optimize dies to enhance the quality, efficiency, and cost-effectiveness of the stamped products.

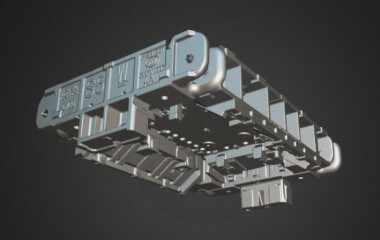

The SCANOLOGY 3D scanner, with its precision and accuracy, is an excellent tool for creating the 3D model of an impeller capturing the shape, curvature, and angles of its blades.

Size is never be a problem for KSCAN 3D scanner. Its high-resolution and precision scanning capabilities allow it to capture even the smallest details of an object.

With the the 3D model of graphite mold casting, engineers can optimize its design, production, and alignment, which improves the quality, and durability of the mold and the castings.

Richiedi una demo

Mentre esplorate i nostri modelli 3D, vi invitiamo a richiedere una demo, che vi permetterà di vedere il mondo attraverso una nuova dimensione. Le vostre richieste sono la nostra priorità e siamo entusiasti di offrirvi un'esperienza diretta della nostra tecnologia 3D all'avanguardia.

Prenota una demo

Compare Products

Compare Products

Tutti i prodotti

Tutti i prodotti