Sfida

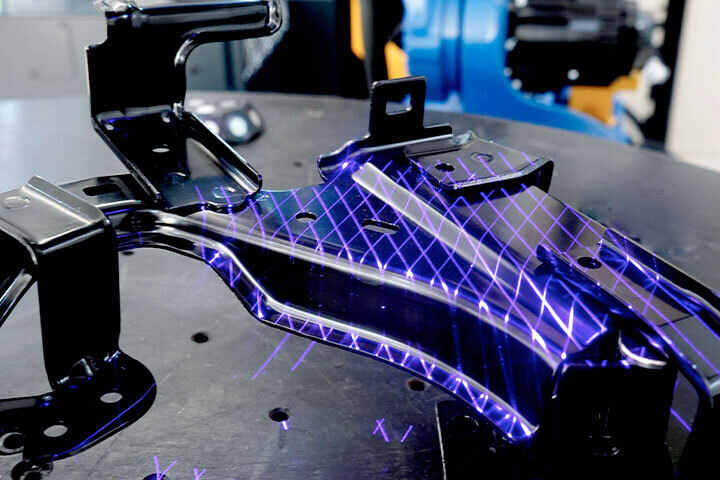

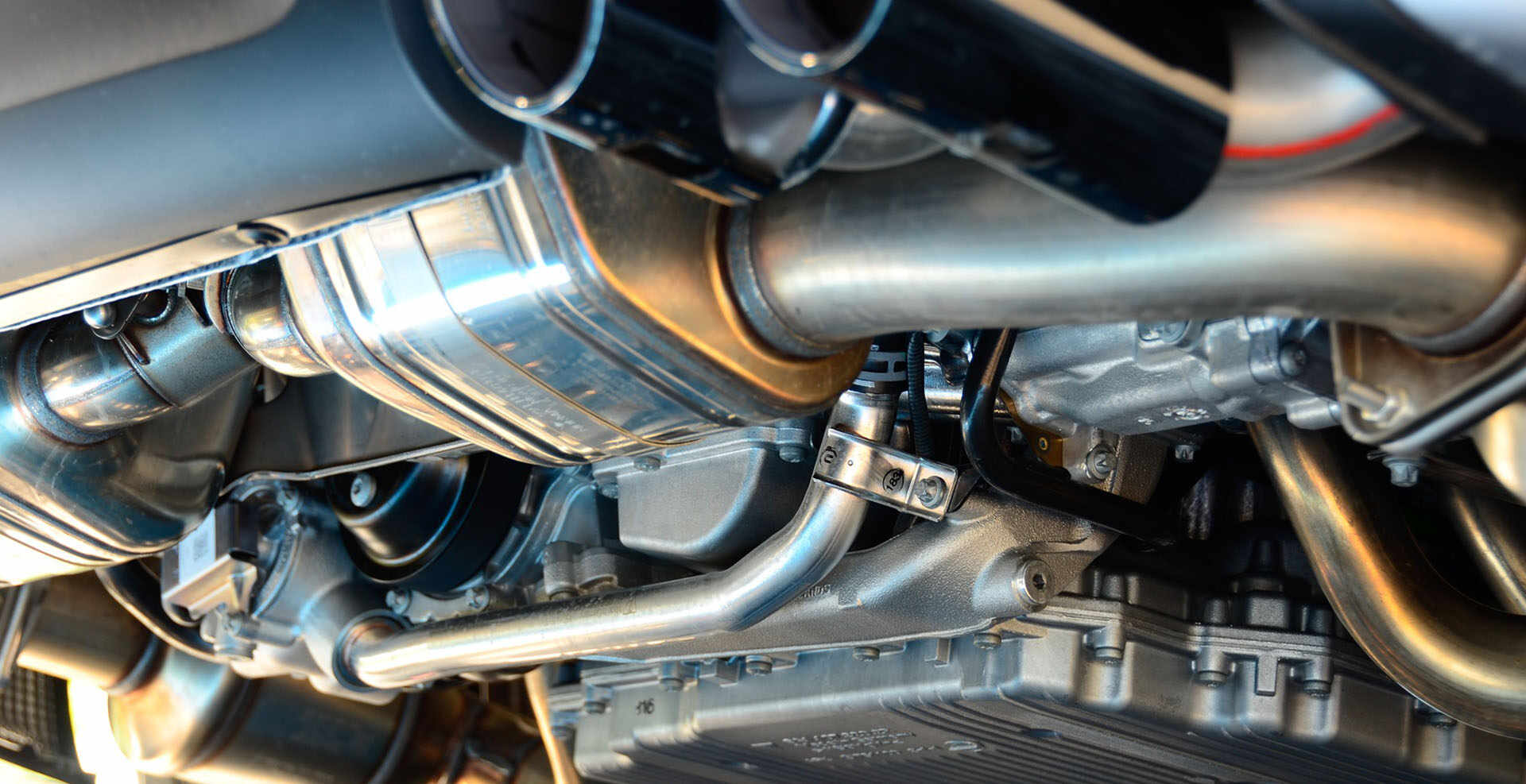

Ispezione 3D della girante per autoveicoli

È difficile testare una girante per autoveicoli, poiché gli scanner 3D con telecamera hanno difficoltà a gestire e acquisire i dati 3D per oggetti dal design complesso, mentre i normali scanner 3D portatili non riescono a raggiungere l'elevato livello di dettaglio richiesto.

Soluzione

PRINCE, grazie alla sua elevata capacità di acquisizione di dettagli elevati, è in grado di ottenere dati 3D accurati per oggetti complessi, fornendo un supporto tecnico altamente efficiente per lo sviluppo e la progettazione del prodotto.

Leggi il caso completo

Tutti i prodotti

Tutti i prodotti

it

it