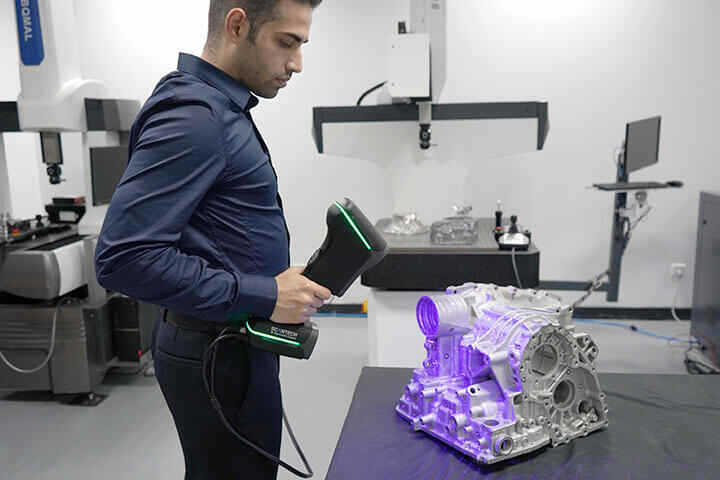

내장된 사진측량 시스템은 체적 정확도를 최대 0.020mm/m까지 향상시키고, 정확도도 최대 0.020mm까지 향상시킵니다. AXE-B11은 추가 장치 없이도 대용량의 전문적인 3D 스캐닝을 제공합니다.

초고속으로 대용량 측정이 초당 1,300,000회의 측정 속도로 가능해져 작업 시간과 인건비를 크게 절감할 수 있습니다.

550mm×600mm의 스캔 영역으로 매우 적은 마커만으로도 스캐닝을 완료할 수 있습니다.

11개의 교차된 블루 레이저와 1개의 추가 블루 레이저 라인 덕분에 AXE-B11은 대규모 스캐닝을 위한 고효율 모드를 지원하고 단일 라인 스캐닝 모드는 깊은 구멍 및 사각 검사와 같은 특수 요구 사항을 충족합니다.

AXE-B11 3D 스캐너는 정확한 참조 막대, 헬퍼 엔지니어 키트 등과 자유롭게 매칭하여 다양한 측정 요구 사항을 충족합니다.

시작할 준비가 되셨나요?

현존하는 가장 진보된 3D 스캐닝 시스템으로 3D 세계를 재건하세요.

기술 사양

기술 사양

| 유형 | 도끼 - B11 | |

|---|---|---|

| 레이저 소스 | 11 파란색 레이저 크로스 + 1 여분의 파란색 레이저 라인 | |

| 깊은 구멍 스캐닝 | 추가 블루 레이저 라인 1 개 | |

| 정확성(1) | 최대 0.020 mm | |

| 측정 속도 | 최대 1,300,000 측정/s | |

| 스캐닝 영역 | 최대 550mm × 600mm | |

| 스캐닝 영역 (사진 측량) | 2500 mm × 3000 mm | |

| 레이저 클래스 | 클래스 safe (눈 - 눈 - 금고) | |

| 해결 | 0.025 mm | |

| 체적 정확도 (추가 장치없이)(2) | 혼자 일하십시오 | 0.020mm+0.035mm/m |

| 1M 참조 막대와 함께 작업하십시오 | 0.020mm+0.020mm/m | |

| MSCAN - L15와 협력하십시오 | 0.020mm+0.012mm/m | |

| 스탠드 - 오프 거리 | 300mm | |

| 피사계 심도 | 500mm | |

| 현장 심도 (사진 측량) | 2500mm | |

| 출력 형식 | .stl, .ply, .obj, .igs, wrl, .xyz, .dae, .fbx, .ma, .asc 또는 customized | |

| 작동 온도 범위 | - 10 ℃ - 40 ℃ | |

| 인터페이스 모드 | USB 3.0 | |

| 특허 | CN204329903U, CN104501740B, CN104165600B, CN204988183U, CN204854633U, CN204944431U, CN204902788U, CN105068384B, CN10504B, CN20490274U CN204963812U, CN204902785U, CN204902790U, CN106403845B, CN209197685U, CN209263911U, CN206905709U, CN107202554B, US20200220A1, US20202250A KR102096806B1, KR102209255B1, US10914576B2, EP3392831A4 | |

(1) ISO 17025 공인 : VDI/VDE 2634 Part 3 표준 및 JJF 1951 사양에 따라 프로브 오류 (크기) (PS) 성능이 평가됩니다.

(2) ISO 17025 공인 : VDI/VDE 2634 PART3 표준 및 JJF 1951 사양에 따라 SPHERE SPACING ERROR (SD) 성능이 평가됩니다.

Compare Products

Compare Products

All Products

All Products