자동차 산업의 Scantech 3D 모델

자동차 산업에서 3D 스캐닝은 필수적이며, 설계, 생산, 품질 관리 및 유지보수 프로세스를 향상시키는 혁신적인 기술입니다. 3D 스캐닝은 설계 및 프로토타입 제작 속도를 높이고 정밀성과 비용 효율성을 보장하는 동시에 물리적 부품의 디지털 3D 모델 생성을 용이하게 합니다. Scantech의 포괄적인 고품질 3D 모델 및 솔루션 제품군은 자동차 전문가들이 설계 및 혁신 프로세스를 혁신할 수 있도록 지원합니다.

Creating a 3D model of a race car seat could improve seat design for driver comfort and safety, virtual testing and cost reduction, customization for individual drivers.

Scantech 3D scanner can create accurate 3D models of Corolla seats, improving ergonomics, reducing development costs, creating digital documentation, and speeding up time-to-market.

Scantech SIMSCAN portable 3D scanner's ability to quickly capture and analyze three-dimensional data contributes to efficient decision-making and improved production processes.

With Scantech SIMSCAN handheld 3D scanner, the manufacturer can accurately assess deformation deviations in the product and make necessary adjustments based on measured values.

Hairpins in motors generally refer to the wire loops used in the stator winding, but here is a 3D model of the newest generation hairpin, bent with solid copper.

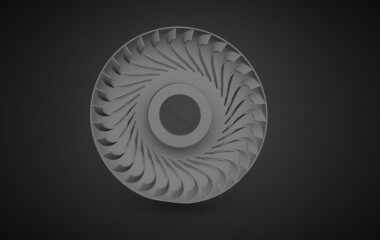

A flywheel can be modeled, balanced, analyzed and inspected by Scantech SIMSCAN handheld 3D scanner with high precision and speed.

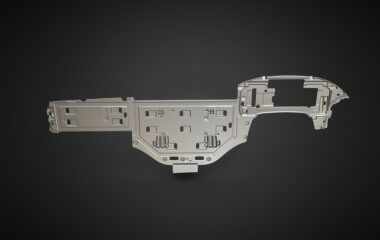

By using Scantech TrackScan-P Optical 3D Measurement System, it's easier to conduct fast and precise inspections of stamping parts.

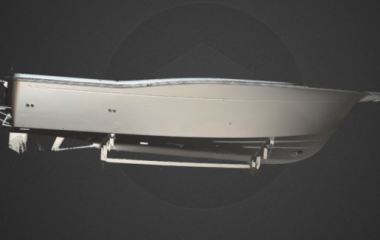

Large object 3D scanning, yacht is hard to scan because of its size. In the project, we use Scantech KSCAN-Magic, built-in photogrammetry function can sovle the problem.

The 3D model of wheel hub can be used to inspect the quality of the wheel by comparing it against the original CAD file. The shape and geometries are accurately obtained.

Scantech 3D scanner enhances car hood design, providing benefits in fit, customization, material optimization, safety features, and overall integration within the vehicle.

데모 요청

제품을 둘러보시는 중 데모를 요청하시면, 3D 기술이 만들어내는 새로운 차원을 직접 체험하실 수 있습니다. 고객님의 문의에 신속히 대응하며, 최상의 경험을 제공해드리기 위해 노력하겠습니다.

데모 예약하기

All Products

All Products

kr

kr