금형 산업의 SCANOLOGY 3D 모델

3D 모델은 설계 프로세스를 간소화하여 금형 개발 시간과 비용을 절감합니다. SCANOLOGY 3D 스캐닝은 금형의 불일치나 결함을 식별하고 수정하여 엄격한 품질 기준을 충족하도록 지원합니다. 또한 역설계를 지원하여 기존 부품을 기반으로 금형을 재현할 수 있습니다. 더 나아가, 금형 업계에서 3D 스캐닝은 금형 복원을 위한 상세한 참고 자료를 제공하여 유지보수 및 수리에 도움을 줍니다.

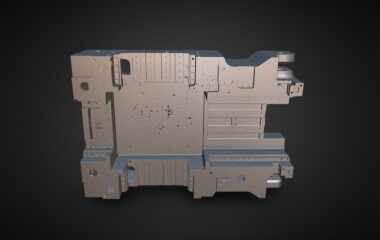

By using the SCANOLOGY KSCAN-Magic 3D scanner to create a 3D model of die casting mold, engineers can achieve high precision in replication, optimization, and prototyping.

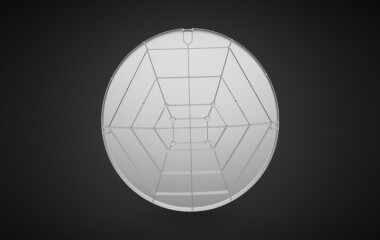

Using the SCANOLOGY SIMSCAN handheld 3D scanner for antenna mold measurement can enhance efficiency, accuracy, and overall quality in the antenna manufacturing process.

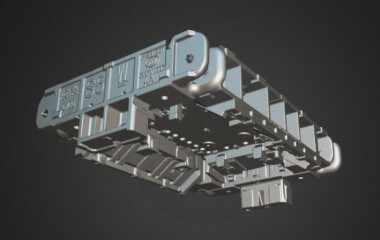

By creating and using the 3D model of stamping die, engineers can design, change, and optimize dies to enhance the quality, efficiency, and cost-effectiveness of the stamped products.

The SCANOLOGY 3D scanner, with its precision and accuracy, is an excellent tool for creating the 3D model of an impeller capturing the shape, curvature, and angles of its blades.

Size is never be a problem for KSCAN 3D scanner. Its high-resolution and precision scanning capabilities allow it to capture even the smallest details of an object.

With the the 3D model of graphite mold casting, engineers can optimize its design, production, and alignment, which improves the quality, and durability of the mold and the castings.

데모 요청

제품을 둘러보시는 중 데모를 요청하시면, 3D 기술이 만들어내는 새로운 차원을 직접 체험하실 수 있습니다. 고객님의 문의에 신속히 대응하며, 최상의 경험을 제공해드리기 위해 노력하겠습니다.

데모 예약하기

Compare Products

Compare Products

All Products

All Products