3D Scanning Enhances Inspection and Product Development in Aviation Industry

The aviation industry continually evolves, with ongoing efforts to refine and improve existing technologies. Within this vast landscape, the development of single-person flight carriers—such as gyrocopters—stands out as an exciting niche.

These compact, lightweight aircraft offer unmatched freedom and mobility, captivating both hobbyists and seasoned pilots.

As the industry evolves, so does the need for meticulous inspection and quality control to ensure these cutting-edge machines meet the highest standards of safety and performance.

NIKI Rotor Gyrocopter Manufacturing Company

NIKI Rotor Aviation, a Bulgarian company, specializes in producing gyrocopters which blend the best of airplanes and helicopters. Founded by an owner with a passion for aviation, NIKI Rotor began as a hobby in a small workshop, where miniature remote-controlled aircraft models took flight.

Today, the company produces fully operational gyrocopters ready for sale.

For Inspection and Product Development

Finished Product Inspection: Utilize a 3D scanner to inspect the finished gyrocopter, ensuring it meets design specifications and quality standards. By capturing precise 3D models of the gyrocopters, dimensions, tolerances, and surface quality can be verified, ensuring the final product is defect-free.

Product Development: Generate an accurate 3D model of the existing gyrocopter frame through 3D scanning to extract geometric data for updating engineering drawings. The measurement assists in analyzing current designs and optimizing product structures.

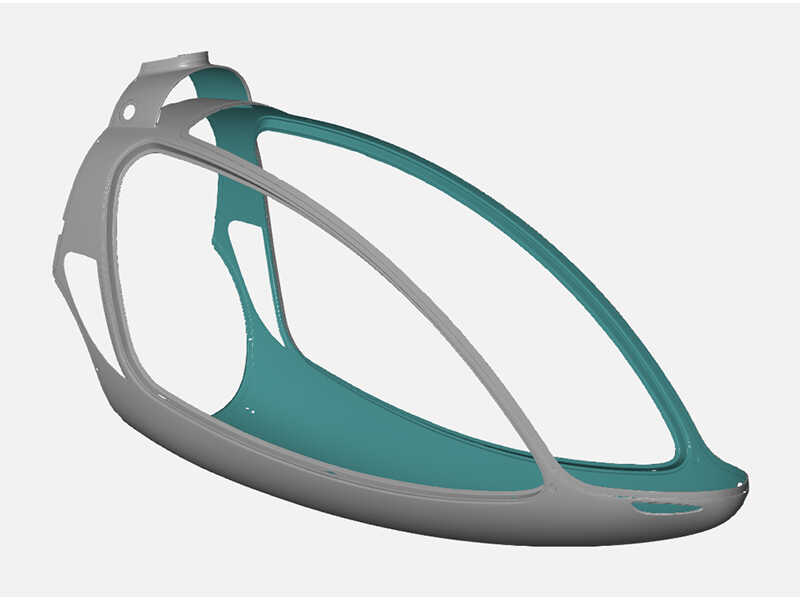

What Part To Be Inspected

One of the primary components NIKI Rotor needs to 3D scan is a large, intricately designed frame of their gyrocopters. This frame, measuring approximately 2m x 1m x 3m, is made of black carbon fiber with a bright yellow paint finish.

Its large curved surfaces add complexity to the measurement process, demanding a high level of accuracy and detail in measurement.

Measurement Challenges

Traditional measurement methods fall short when faced with such a complex and sizable component. The primary challenges include:

· High Precision Requirements: Ensuring flight safety necessitates high precision in the manufacturing and inspection of gyrocopter parts, often at the micron level.

· Wide Range of Sizes: Gyrocopter components vary significantly in size, from small precision parts to large structural components.

· Complex Geometries: Gyrocopter components typically have intricate curves and geometric shapes, including rotor blades and fuselage structures.

· Surface Characteristics: Carbon fiber, particularly in black, poses significant challenges for conventional scanning techniques.

· Time-Consuming Processes: Traditional probe measurements are time-intensive, making them impractical for such large parts.

Scantech’s 3D Solutions

To address these challenges, NIKI Rotor turned to Scantech’s cutting-edge 3D scanning technology, specifically the TrackScan-Sharp optical 3D measurement system to capture highly accurate and detailed 3D data.

This system offers a range of features tailored to meet the demands of inspecting complex, large-scale parts.

Scanning Process

The TrackScan-Sharp system employs advanced blue laser technology, which is particularly effective for scanning carbon fiber and black surfaces. The scanning process, which can be completed in approximately 10 minutes, involves the following steps:

· Setup: Positioning the TrackScan-Sharp to cover the entire component.

· Scanning: Utilizing the blue laser to capture detailed measurements without the need for targets.

· Data Collection: Gathering comprehensive data to create precise color maps.

Benefits of 3D Solutions

The advantages of using Scantech’s 3D solutions are manifold:

· Accuracy: TrackScan-Sharp can measure the dimensions and tolerances of gyrocopter components accurately with accuracy of up to 0.025 mm , ensuring they meet design specifications and quality standards. The blue laser technology ensures accurate scanning of carbon fiber and black surfaces.

· Efficiency: The TrackScan-Sharp’s large tracking volume allows for a complete scan in a single shot, significantly reducing inspection time.

· Simplicity: The system’s ability to scan without targets simplifies the process.

For Inspection

· Surface Quality Assessment: High-resolution scanning allows for detailed inspection of surface quality, identifying any defects or imperfections that may affect performance.

· Data Clarity: The resulting comparison drawings clearly highlight discrepancies between the CAD model and the actual component, providing essential data for design corrections and improvements.

For Product Development

· Accurate 3D Models: The system generates precise 3D models of existing gyrocopter parts, facilitating the extraction of geometric data needed for creating or updating engineering drawings.

· Design Optimization: Detailed scans enable the analysis of current designs, identifying areas for improvement and optimization.

Conclusion

Trackscan-Sharp provides valuable data support, enabling customers to correct CAD designs and improve overall product development. By doing so, it accelerates the research and development cycle while minimizing trial-and-error costs.

Additionally, this versatile scanner can be utilized for quality inspection and control during production. NIKI Rotor Aviation’s commitment to innovation and precision has positioned them at the forefront of gyrocopter manufacturing.

With the integration of Trackscan-Sharp, they not only address inspection and development challenges but also empower their clients to confidently take flight.

All Products

All Products

en

en