Global 3D Scanner

Designed for Large-scale Project

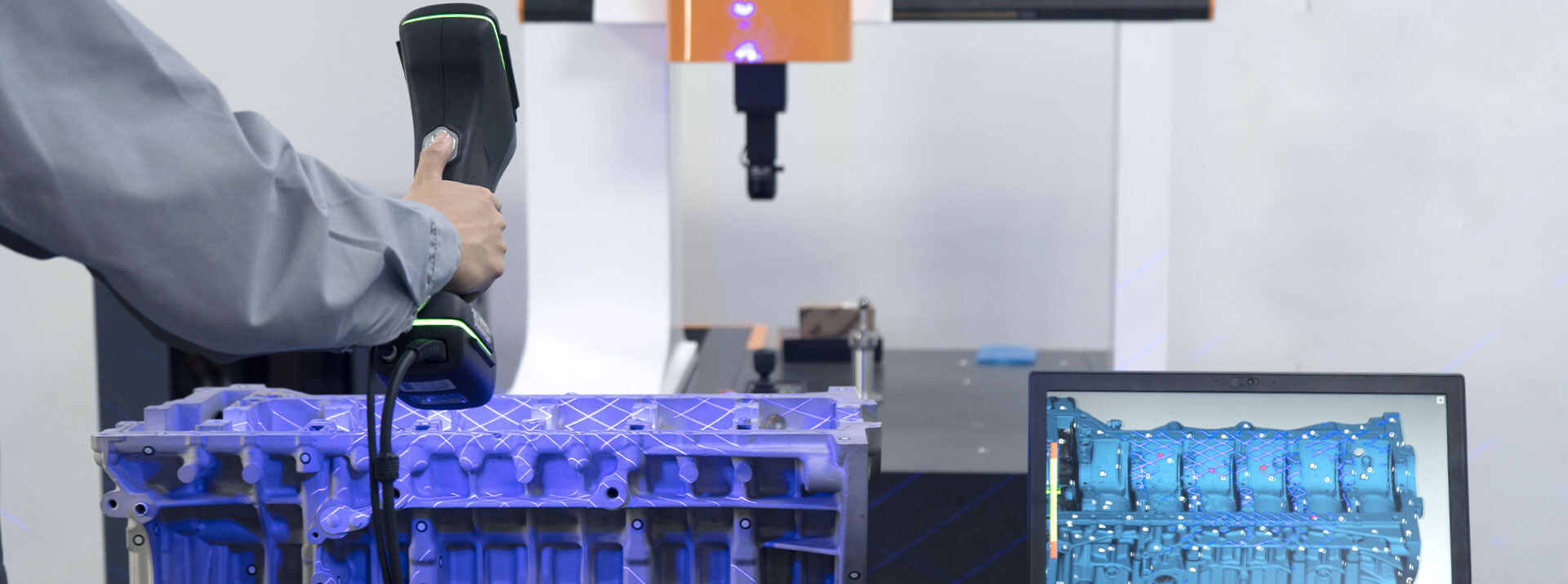

Tailored for measuring large-scale objects, our global 3D scanners are specially designed to overcome the challenges inherent in 3D inspection of expansive projects. Equipped with a built-in photogrammetry system, these scanners deliver metrology-grade 3D solutions without the need for additional devices. The innovative technology embedded in this type of 3D solution addresses issues related to scanning area and volumetric accuracy, offering an ultra-wide scanning area and precise data collection.

When dealing with large-scale projects, efficiency is paramount. Our large scale 3D scanners leverage the power of the built-in photogrammetry system to enhance the efficiency of high-quality 3D modeling and accelerate the entire 3D digitizing process. Trust in our advanced technology to streamline your workflow and provide exceptional precision in 3D measurements.

AXE-B 3D Scanner

The built-in photogrammetry allows to conduct large-sized measuring just by one handheld 3D scanner. When working with Scantech automated 3D system, AXE 3D scanner will realize continuous online batch 3D inspection.

What is the best 3D scanner for your demands?

SCANTECH 3D is a global leader in 3D scanning technology, providing non-contact measurement technology of the optical scanners coupled with precision measurement within product cycle times. Discover more Scantech 3D metrology solutions for you.

While dealing with the 3D inspection of sizable projects, one invariably encounters challenges concerning scanning area and volumetric accuracy. To address these challenges, Scantech global mobile 3D laser scanners have been specifically crafted for the measurement of large-scale objects.

Scantech 3D mobile laser scanning service leverages innovative built-in photogrammetry system technology to offer an extraordinarily extensive scanning area and precise data collection capabilities. This not only enhances the efficiency of producing high-quality 3D models but also significantly expedites the 3D digitization process. To gain further insights, please refer to the details provided below.

AXE-B Series 3D Scanner |

|

|---|---|

| Accuracy | Up to 0.020 mm (0.0008 in) |

| Scanning rate up to | 2,000,000 measuremnets/s |

| Scanning area up to | 860 mm × 600 mm (33.9 in × 23.6 in) |

| Resolution up to | 0.025 mm (0.0009 in) |

Cooperate with top-rate 3D scanner provider

Enable you to measure and scan everything

Scantech 3D Mobile Laser Scanner Solution Designed for Unique Needs of Different Industries

Find out how our 3D portable scanner helps.

Global Mobile Laser Scanner for Railway & Ships, and Energy & Heavy Industry

Railway & Ships

In the railway and ship industries, Scantech’s mobile 3D laser scanners provide highly accurate and detailed 3D data, making them valuable tools for maintenance, safety, and efficiency improvements. Their ability to enable proactive maintenance, reduce downtime, and enhance reliability is crucial for the success of operations in these sectors.

The smoothness of the railway track has a direct impact on the quality of the train’s operation. Scantech mobile laser scanners capture detailed 3D data of the tracks, enabling the detection of issues such as track geometry deviations, wear, and damage. This data is critical for maintaining safe and efficient railway operations.

Scantech 3D mobile laser scanning devices are used to assess the condition of railway bridges, tunnels, and related infrastructure. They can detect structural deformations, cracks, and other potential hazards, facilitating timely maintenance and ensuring railway safety.

Scantech portable 3D mobile scanners help ensure safety by measuring clearances between objects (e.g., trains and platforms) or obstacles (e.g., ships and navigational hazards). They contribute to collision avoidance and safety compliance.

Energy & Heavy Industry

Scantech 3D laser scanners serves as an indispensable tool in the energy and heavy industry, enabling precision, efficiency, and safety. They facilitate accurate data capture and analysis for various applications, from power plant design and maintenance to heavy manufacturing quality control. Scantech 3D scanners contributes to improved operational performance, safety, and resource utilization in these critical industries.

In the energy and heavy industry, the safety and reliability of large machinery and equipment is critical. Scantech 3D mobile scanners can be used to regularly inspect and maintain equipment such as generators, turbines and boilers. By scanning the surfaces of critical components, potential wear, corrosion or damage can be detected, enabling timely repairs and preventive maintenance and reducing downtime.

Scantech’s 3D Scanners mobile can be used to monitor changes and deformations in critical structures, helping to ensure the safety of plants and equipment. In addition, they can be used for quality control, checking that the size and shape of products and components meet specifications to ensure the quality of the products produced.

In the field of energy and heavy industry, a number of tasks require measurements and analysis on-site, such as the monitoring of building structures or the installation of equipment. Scantech 3D portable scanners are mobile and can be used to take fast, highly accurate measurements on-site and then compare and analyze the measured data with the design.

Various 3D scanning solutions for your 3D measurement needs

With SCANTECH's cutting-edge 3D scanning technology,

you can trust that you are using a reliable and effective 3D scanning solution that delivers high-quality results.

All Products

All Products

en

en