Automation Enables Intelligent Manufacturing

Guided by the concepts of ‘Industry 4.0’ and ‘Smart Factory’, a wide range of industries, including the automotive, aerospace, mold, and manufacturing are seeking for factory automation to enhance intelligent manufacturing.

An automated inspection involves automating one or more steps in the inspection process. Automated 3D inspection can help to generate repeatable and accurate measurement results for manufacturers, who can use the feedback data to monitor the manufacturing process in time. In this way, manufacturers can shift from preventative to proactive quality control.

How to Use Automated 3D Measurement Systems in Inspection ?

Deployment

Quick on-site installation

Operation

Plug-and-play concept with intuitive workflows

Automated Measurement

Non-stop and automated 3D measurement for parts in a large volume

Intuitive Reports

Visual inspection reports with precise and repeatable results

Benefits

Automated 3D inspection systems can speed up outputs by 24-hour non-stop operations. Thanks to its easy operation and preset measurement paths, automated 3D inspection systems enable engineers with different levels of expertise and programming skills to operate with ease.

Automated systems are designed to measure parts made in different materials with all kinds of finishes that comes in small, medium to large sizes. These systems help to reduce costs, increase profits, and enhance intelligent manufacturing, allowing manufacturers to face challenges in ever-growing and demanding markets.

X0 mm

Increase Efficiency, and Double Profits

Automated inspection systems allow users to inspect hundreds of parts a day without any breaks, even when the parts are complex. The measurement process is further accelerated by eliminating the need for a specialist or metrologist to load, operate, and unload the machine. Furthermore, it helps reduce the rate of production errors and production time to enhance profits.

<0 day

Training

By offering turnkey solutions, automated measurement systems make operation as easy as possible regardless of the expertise of engineers and operators. The simple set-up and operation of these systems allow engineers to operate them smoothly with minimal training. These systems also support customization to meet different demands.

0%

Improve Upstream Process

Monitoring the manufacturing process in real time is made easier with automated inspection. It provides a significant amount of data for identifying deviations. The feedback data can be analyzed to improve the upstream process. The factory can shift from preventative to proactive quality control by doing so.

Application Scenarios

Aerospace

Improve efficiency and security compliance in the aerospace industry with automated inspection system and quality management software processes. From measuring large-scale wing spars to measurements of fasteners for the airplane skins, our systems make sure your parts meet the highest quality compliance standards.

Automotive

Efficient and accurate inspections are essential for auto manufacturers to maintain an edge over competitors. With automated measurement systems, you can efficiently inspect and analyze surface deviation, hole diameter, hole position, hole-to-hole distance, boundaries, and more for parts in batches.

Energy & Heavy Industry

The measurement process is typically more accurate with automated inspection systems than with humans. Consequently, product quality can be controlled and maintained more consistently. With automation, equipment and processes are streamlined, scrap is reduced and space is saved.

Mold

Automation in manufacturing and precision measurement will aid mold builders in increasing their productivity by measuring more dimensions on more parts without compromising accuracy. Taking a large number of data, they can get more insights into manufacturing and take corrective actions to improve workflows for better quality control and meet higher industry standards.

Scantech Solutions 3D Scanning Solution

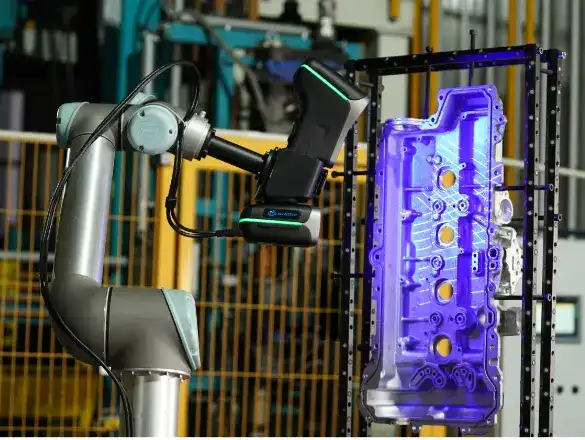

Scantech’s automated inspection system mainly consists of an automatic handling system, a robot-mounted 3D scanner, and 3D measurement system. The system can measure up to hundreds of parts a day so it greatly speeds up outputs. Automating procedures also decreases possible errors that result from manually performed work.

These turnkey solutions save the hassle of designing and assembling a measurement system and can also be customized to meet different demands. Due to its simple user interface, users don’t need much training to operate. Measurement software that goes with these systems makes it easy for manufacturers to detect defects and deformations and adjust the manufacturing process accordingly.

All Products

All Products

en

en