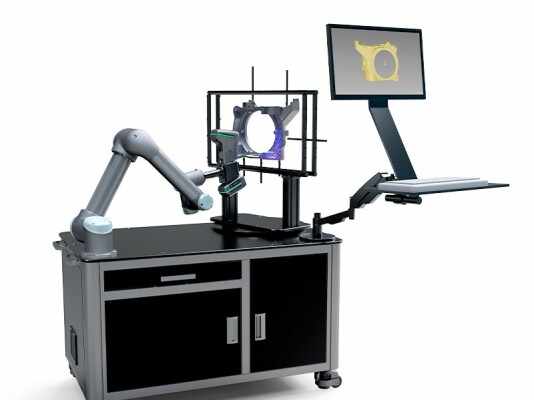

Automatic Whole-process Inspection

Without human involvement, AutoScan-K is an automated 3d scanner that can automatically conduct batch 3D scanning and inspection for data comparison, and generate inspection reports, after scanning routes and measurement process are set for different products.

All Products

All Products

en

en