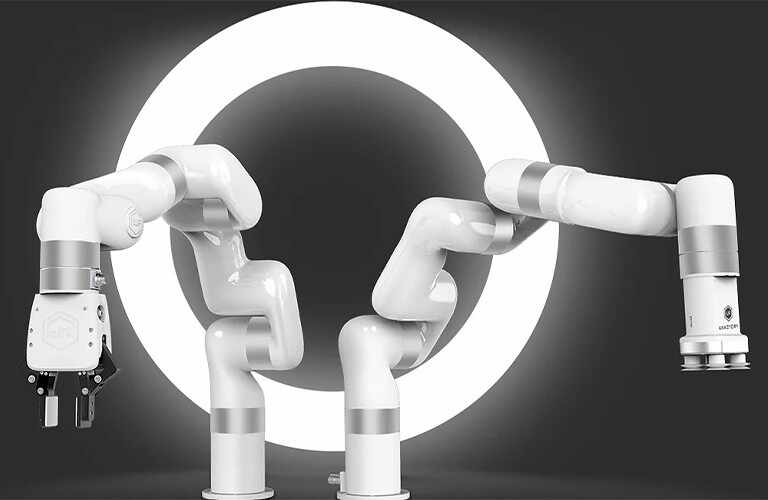

M-Track Intelligent Robotic Path Planning and Guiding System

6D Pose Recognition

Intelligent and Efficient

Automatic Path Planning

Highly Safe and Reliable

Experience the Performance of Portable 3D Scanners

Whether you are in the lab, on the shop floor, or out in the field, you need to rely on portable, metrology-grade 3D scanners that pack a true punch in terms of ease of use, accuracy, resolution, reliability and fast data acquisition.

Contact NowIntelligent and Efficient Path Planning

Track is an optimal solution for manufacturers to plan robotic paths as it is flexible, reliable, and highly adaptive to environmental changes. It helps robots reach the target position accurately to complete the preset task.

By identifying the positions and orientations of a tool simulator in the workspace, M-Track’s tracking system can transmit the information to path planning software. Its path planning software can automatically devise a safe and effective path ready for execution.

Accurate 6D Pose Tracking

Based on stereoscopic vision technology, the tracking system can accurately and efficiently capture the path of the tool simulator. It supports the accurate output of 6D poses of the simulator and comprehensively captures the pose of the tool center point.

M-Track’s high-precision tracking ensures appropriate path planning and safe operation of robots. Its accuracy reaches 0.049 mm when the tracking range is 10.4 m³ and 0.067 mm for 28.6 m³, and 0.089 mm for 49.0 m³.

Convenient and User-friendly Operation

The system can be used directly without complex programming. Its tool simulators 3D printed in the form of actual tools are easy to use. Whether you are a professional engineer and a novice, you can know how to use it regardless of your level of expertise.

It can simulate the motion of human operations in a real workspace. Its behaviour-based simulation allows path planning more adaptive to real-world working conditions and production needs. The path can be saved for future use with just a few clicks.

Highly Adaptive for Vast Applications

The automated smart robot path planning system comprises perception, planning, and execution modules, which cater to different applications such as grinding, coating, welding, and more.

The robotic path planning software is compatible with various robots, including ABB, KUKA, FANUC, and EFFORT. It supports the planning of lines, curves, etc. Be it indoor or outdoor, structured or unstructured environment, it is capable of meeting different requirements for different industrial scenarios.

Ready To Get Started?

Rebuild our 3D world with the most advanced 3D scanning system available.

Request A DemoTechnical Specifications

| Type | M-Track Intelligent Robotic Path Planning and Guiding System | |

| Tracking accuracy | 10.4 m³ (Tracking distance 3.5 m) | 0.049 mm (0.0019 in) |

| 28.6 m³ (Tracking distance 5.0 m) | 0.067 mm (0.0026 in) | |

| 49.0 m³ (Tracking distance 6.0 m) | 0.089 mm (0.0035 in) | |

| Robot models supported | ABB/KUKA/FANUC/EFFORT, etc | |

| Tracking frequency | 60 Hz | |

| Tool simulator | Custom | |

| Operating temperature | -10 ℃–40 ℃ | |

Download Brochure

We invite you to download our detailed brochure. SCANTECH provides comprehensive solutions to frequently asked queries about our 3D scanner.

High-tech 3D Scanners

SCANTECH’s handheld 3D scanners power the 3D scanning services. These instruments can obtain precise point clouds, which can be triangulated into a polygon mesh or STL file.

Due to their high precision, versatility, and portability, they can fulfill various metrology-grade 3D scanning projects.

Interested in the M-Track Intelligent Robotic Path Planning and Guiding System ?

We highly encourage you to consult with an expert from Scantech. Our experienced professionals are proficient in identifying optimal solutions tailored to your requirements.

Contact Now

All Products

All Products

en

en