MSCAN-L15 Photogrammetry System

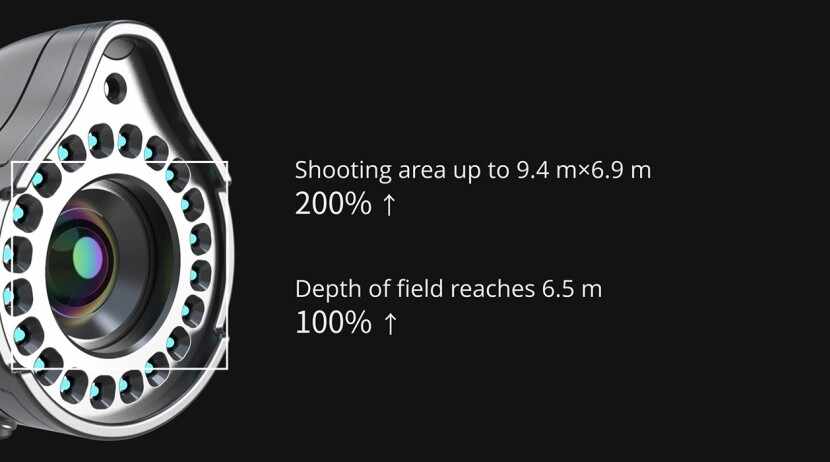

MSCAN-L15 photogrammetry system, tailored to deliver high-precision geometric measurements for large-scale workpieces. With a vast shooting area and wide depth of field, the MSCAN-L15 achieves a volumetric accuracy of 0.012 mm/m, ideal for projects ranging from 2m to 10m in size.

Compatible with 3D inspection devices, the MSCAN-L15 meets stringent measurement accuracy requirements effortlessly. Its unique HDR mode ensures adaptability to varying environments. Moreover, its ergonomic design ensures excellent portability, allowing for prolonged usage without discomfort.

Experience precise, efficient, and user-friendly 3D solutions for large-scale projects in 3D inspection, product development, quality control, and more with the MSCAN-L15. Unlock the potential of photogrammetry and 3D scanning technology with this cutting-edge system.

Volumetric Accuracy of 0.012 mm/m

Scanning Objects from 2 m to 10 m

Unique HDR Mode

Experience the Performance of 3D Photogrammetry

Immerse yourself in the precision and detail of 3D photogrammetry. Transform images into stunning 3D models with incredible accuracy. From documenting artifacts to industrial inspection, experience its versatility across industries.

Contact NowUnique HDR Mode

Deformation Detection

Multi-adaptors

Ready To Get Started?

Rebuild our 3D world with the most advanced 3D scanning system available.

Request A DemoTechnical Specifications

| Type | MSCAN-L15 | |

| Volumetric accuracy | 0.012 mm/m (0.00014 in/ft) |

|

| Volumetric accuracy (work with 3D scanners) | KSCAN | 0.015 mm + 0.012 mm/m (0.0006 in + 0.00014 in/ft) |

| SIMSCAN | 0.015 mm + 0.012 mm/m (0.0006 in + 0.00014 in/ft) |

|

| AXE | 0.020 mm + 0.012 mm/m (0.0008 in + 0.00014 in/ft) |

|

| TrackScan | 0.044 mm+0.012 mm/m (0.0017 in + 0.00014 in/ft) |

|

| Device type | Industrial camera and lens (not DSLR) | |

| Weight | ≤0.58 KG (≤1.28 lb) | |

| Obtain mark point position | Real-time calculate & display | |

| Interface mode | Gigabit Lan | |

| Depth of field | 6.5 m (255.9 in) | |

| Shooting area up to | 9.4 m x 6.9 m (370.1 in × 271.7 in) |

|

| Operating temperature range | -10℃-40℃ (14℉-104℉) | |

| Patent | CN306051753S | |

Download Brochure

We invite you to download our detailed brochure. SCANTECH provides comprehensive solutions to frequently asked queries about our 3D scanner.

High-tech 3D Scanners

SCANTECH’s handheld 3D scanners power the 3D scanning services. These instruments can obtain precise point clouds, which can be triangulated into a polygon mesh or STL file.

Due to their high precision, versatility, and portability, they can fulfill various metrology-grade 3D scanning projects.

Related Case

Interested in the MSCAN-L15 Photogrammetry System?

We highly encourage you to consult with an expert from Scantech. Our experienced professionals are proficient in identifying optimal solutions tailored to your requirements.

Contact Now

All Products

All Products

en

en