Revolutionizing Car Design and Production with 3D Car Scanning

Car designers and production engineers work together to achieve the perfect design of a car, which requires a harmonized combination of aesthetics and functional requirements. Generally, it takes several years to turn a design concept of a new car model into an actual product available to the market.

A wide range of EMOs and automotive part suppliers are involved in designing, developing, and manufacturing motor vehicles. They are meeting the challenge of designing cars in a short amount of time to meet the fast-paced growth of the market. Cutting-edge technologies, including 3D scanning, are what they seek to reform the automotive industry.

Scantech allows automakers to tap into their potential to the full by capturing full-field and accurate 3D data of automotive parts with our high-precision 3D scanners and automated 3D measurement solutions. It is a way for them to accelerate product development and streamline workflows of inspections. It helps them to yield enormous benefits in quality and efficiency.

Guarantee the Quality with 3D Metrology Solutions

Carlight

Grille

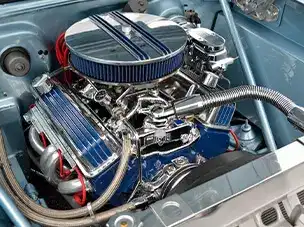

Engine Pipe

Stamping Part

Car Seat

Foot Pad

Paint Protection Film

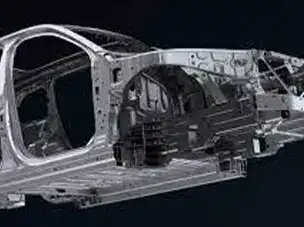

Body-in-white

Precision 3D Scanning for Automotive Inspection & Customization

Scantech’s 3D scanners support on-site and non-contact measurement, efficiently delivering precise measurement data. These 3D scanners can be used for off-line, near-line, or in-line measurements. Through an advanced algorithm, our devices scan and generate real-time point clouds using blue lasers. With a variety of scanning angles, users can capture data deep within the gap or along the edge of the parts. The data from white-in-body and sub-assemblies that have been scanned can be stored digitally. Having complete inspection data allows users to identify issues that cannot be detected during the early stage.

Inspection of Car Body

In order to assemble a car correctly, the body-in-white must be carefully inspected to ensure the parts are matched and that the connecting features are aligned correctly. Automotive assembly lines have hundreds of inspection points, including in-process monitoring, subassembly monitoring, and critical inspection of many points on the assembled body-in-white. Complex features to be inspected include surfaces, holes, slots, nuts, and studs, which vary in materials and colors. Scantech’s handheld 3D scanner doesn’t require rigid measurement setup and can handle various inspection tasks. Critical parameters can be easily obtained for a wide range of uses.

Learn More >

Automotive Gap & Flush Inspection

A car that is less aerodynamically designed is more prone to wind noises. The manufacturer must identify the hidden reasons to ensure a smooth and quiet ride for further customers. By tracing the data captured by a 3D scanner, automakers can analyze the dimensions of the door surface and gaps between doors and mounted vehicle bodies. Scantech’s lightweight 3D scanner KSCAN-Magic is equipped with five working modes, including large area scanning and superfine scanning. By conducting on-site inspections, technicians can obtain the 3D data, verify possible reasons and identify problems quickly.

Learn More >

Supplier Quality Assurance

Automakers rely on suppliers to provide high-quality and customized products in manufacturing. Supplier quality engineers traveled back and forth between supplier locations to survey quality systems. Scantech’s portable and handheld 3D scanners KSCAN-Magic can conduct on-site inspections under harsh conditions. It can easily capture data on complex surfaces and narrow spaces with an accuracy of up to 0.020 mm. Our 3D scanners are trusted solutions to guarantee internal quality controls.

Learn More >

Automated Inspection of Stamping Parts

We provide customers with customized automated 3D inspection solutions. Automated optical tracking measurement technology enables engineers to perform non-contact measurements without sticking markers. In this way, we minimize preparation time for scanning and avoid potential damage to the workpiece. With our in-house developed AutoScan-T, we can inspect and analyze surface deviation, hole diameter, hole position, hole-to-hole distance, boundary, and gauge of its stamping parts. Thanks to the portability and robust performance, Scantech’s automated 3D measurement system can support efficient and full-field geometry acquisition.

Learn More >

Car Modification

Automotive Interior Customization Applications for automotive interior customization include fit-outs of van interiors, development of accessories such as car floor mats, seat covers, screens for dashboards, navigation, audio, etc. Our 3D laser scanners conduct non-contact 3D measurements not limited by different shapes and angles. The scanning rate of our 3D scanners can reach a million times per second. The complete data our 3D scanners deliver can serve as a precise basis for further design of the center console, seat, and mat floor.

Learn More >Traditional Gauge VS SCANTECH’s 3D Scanner

Traditional Inspection Gauge |

Scantech’s Handheld 3D Scanner |

| ● Limited data collection

● Non-repeatable measurement results ● Time-consuming ● Large footprint required to store tools |

● No rigid setup is required

● Fast measurement ● Full-field data collection ● Immune to plant floor vibrations ● Faster calculation ● Intuitive Reports |

3D Scanning for Automotive Applications

From design and rapid prototyping to reverse engineering and quality inspection, 3D scanners have integrated into automakers’ technology toolsets. They enable automotive manufacturers to capture precise, measurable 3D data from components of all sizes.

Whether restoring a classic car or developing a new prototype, Scantech 3D scanners provide high-accuracy 3D surface data at every stage of car manufacturing process.

Scantech 3D Scanner

Scantech 3D scanners deliver efficient, high-resolution scanning of automotive parts, from exterior body panels to intricate engine components, ensuring accuracy and precision across diverse applications.

Talk to an expert

Engage in a conversation with a specialist to discover how our 3D scanners can enhance the quality inspection process tailored to your industry's needs.

All Products

All Products

en

en