Why 3D Vision Will Gradually Replace 2D Recognition Technology

2D vision systems have been in use for decades and have performed well in certain applications. However, they have inherent limitations, particularly in complex scenarios where they cannot fully meet the requirements.

With the rise of 3D vision technology, many of these limitations are being addressed.

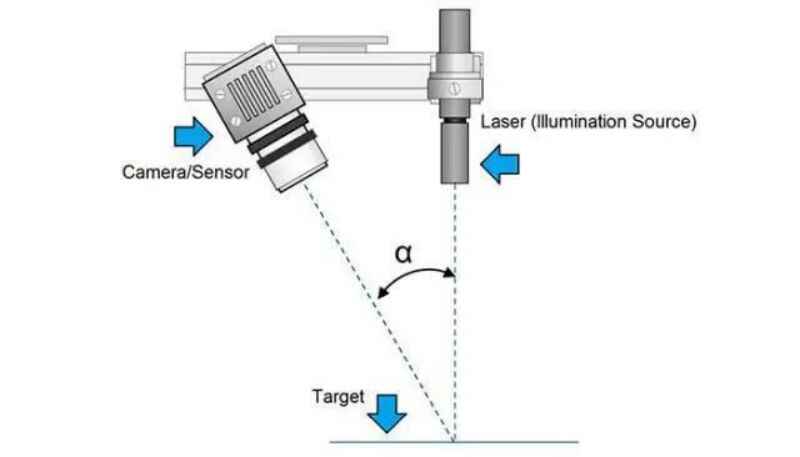

While 2D vision systems utilize CCD or CMOS cameras to capture two-dimensional data, 3D vision systems employ a range of sensors, such as structured light, laser triangulation, or time-of-flight sensors, to gather three-dimensional information.

Both types of systems share common components, including light sources, optical lenses, image processing software, and communication interfaces, but they differ fundamentally in how they capture and interpret visual data.

Let’s explore the differences between 2D and 3D vision systems, their operating principles, and their respective application areas.

What is a 2D Vision System?

In a 2D vision system, the captured image is a two-dimensional (2D) representation of the target. This means that the system only processes X and Y axis information and lacks depth or Z-axis data.

In other words, 2D vision can only provide a contour of the object without conveying height information. As a result, 2D vision has limitations in applications where precise shape information is required.

However, 2D vision still performs well in simpler tasks such as feature recognition, positioning, size detection, barcode reading, character recognition, label verification, quality inspection, and target tracking.

Limitations of 2D Vision

• Light Sensitivity: 2D vision systems rely on the reflected light from the object, so changes in ambient light or fluctuations in the light source can affect accuracy. In factory environments, excessive or insufficient light or shadows may blur the edges and features in the image, leading to incorrect detection.

• Contrast Issues: 2D vision depends on the contrast of the object’s surface. For objects that are too bright or too dark, even with different lighting setups, it may be difficult to accurately capture edges and features, affecting system performance.

• Lack of Depth Information: As 2D vision cannot capture height information along the Z-axis, any height variation in the target object can result in imaging errors and inaccurate measurements.

• Inability to Handle Complex 3D Shapes: 2D vision systems struggle with complex three-dimensional shapes, particularly when the task requires measuring dimensions that extend beyond the X or Y planes, making them unsuitable for tasks like precise volume detection or pick-and-place operations.

Basic Principles of 3D Vision

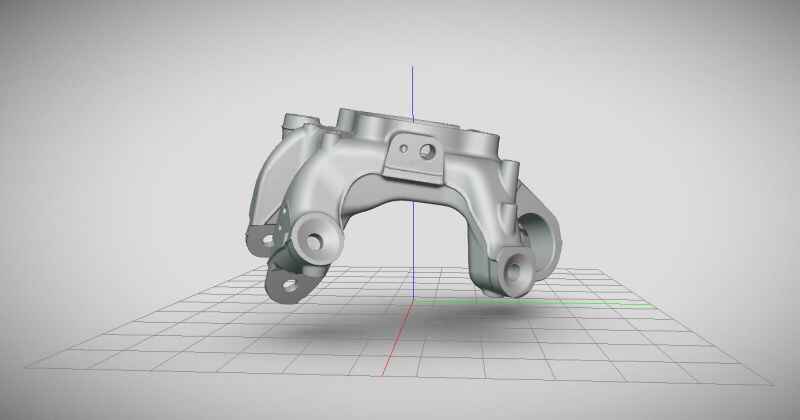

A 3D vision system captures not only a two-dimensional image but also generates a precise 3D point cloud, which enables the system to identify the position of each pixel in space.

This means the system can capture X, Y, and Z axis data, along with rotation information around each axis.

Common technologies used to implement 3D vision include laser triangulation, stereo vision, time of flight, and structured light.

While processing 3D data requires more time, computing power, and software support than processing 2D data, advancements in multi-core processors, 3D algorithms, and software tools have made 3D vision systems capable of meeting production line throughput requirements.

Furthermore, by reliably capturing 3D data, 3D vision systems overcome the limitations of 2D systems, such as sensitivity to lighting, contrast, and object distance.

Advantages of 3D Vision

When using 3D vision, the system can accurately process the shape and position of an object based on its high-precision 3D digital model.

The can precisely identify the object’s position, volume, angle, flatness, and features in space, without being affected by changes in the production line environment or the reflective or absorptive properties of the object’s surface.

This simplifies system design significantly and extends functionality to handle tasks that 2D vision systems cannot, such as complex part handling, detection, and assembly.

Moreover, 3D vision provides an efficient and cost-effective solution for tasks that 2D systems cannot achieve.

Although there are significant differences in quality and performance among different 3D vision technologies, selecting the right technology is more complex than choosing a traditional camera, as factors such as resolution, color, speed, and accuracy must be considered.

Applications of 2D and 3D Vision Systems

2D Vision Applications

• Feature Recognition: Used in manufacturing for identifying components based on predefined features, such as logos or patterns.

• Barcode Reading: Commonly employed in retail and logistics for fast inventory management and product tracking.

• Size Measurement: Applied in quality control to ensure products meet specified dimensions without requiring depth information.

• Character Recognition: Utilized in document processing and OCR (Optical Character Recognition) systems to convert printed text into digital format.

• Label Verification: Important in packaging industries to confirm the accuracy of labels and their placement on products.

3D Vision Applications

3D vision systems are increasingly adopted in applications requiring detailed spatial information and complex data interpretation. Key applications include:

• Thickness and Volume Measurement: Essential in industries such as manufacturing and construction for ensuring product specifications are met.

• Surface Defect Detection: Employed in quality assurance processes to identify flaws or inconsistencies on product surfaces.

• Complex Shape Recognition: Used in automated assembly and manufacturing processes where intricate shapes must be identified and handled accurately.

• Robotic Guidance: Crucial for autonomous robots in tasks like picking and placing objects, where precise spatial information is required.

• Part Assembly: Facilitates the assembly of components by providing accurate height and position data, ensuring correct alignment.

Scantech enhances the capabilities of 3D vision systems with its range of advanced 3D scanners. These scanners utilize cutting-edge technologies such as structured light scanning and laser triangulation to deliver rapid and highly accurate data collection.

They are specifically designed for various applications, including product development, inspections, and complex assembly tasks.

With their ability to capture intricate details and generate precise 3D models, Scantech’s scanners enable industries to improve productivity, streamline workflows, and ensure superior product quality.

Conclusion

3D and 2D vision systems differ significantly in terms of data representation, processing methods, spatial perception, application areas, and algorithms.

While 2D vision primarily relies on flat image analysis for simpler tasks, 3D vision offers more precise depth sensing and spatial positioning, making it ideal for advanced applications such as robotic navigation and complex shape recognition.

In some scenarios, 2D vision is sufficient to meet the requirements. However, for applications requiring higher precision and spatial information, 3D vision offers a clear advantage.

The choice of vision technology should be based on the specific application needs and environment.

All Products

All Products

en

en