Digitizing a Cobra Helicopter with NimbleTrack to Unlock 3D Scanning Potential

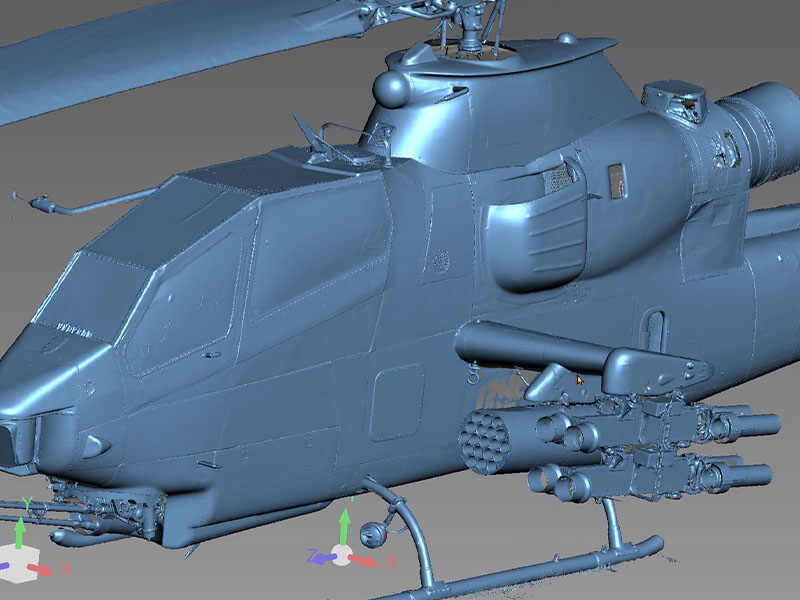

In the ever-evolving world of 3D scanning, Digitize Designs, in collaboration with Scantech, undertook the impressive task of digitizing a retired Cobra helicopter.

This case study exemplifies how real-world objects can be meticulously transformed into digital models, showcasing the remarkable capabilities of the NimbleTrack 3D scanning system, a completely wireless and portable solution.

Challenges of 3D Scanning a Helicopter

3D scanning a retired Cobra helicopter presents several unique challenges due to its size, shape, structure, and materials.

Here are some key considerations:

Complex Geometry: The helicopter’s intricate design, including its rotors, tail boom, and mechanical parts, demands high-precision scanning to capture fine details accurately.

Accessibility: Some parts of the helicopter may be difficult to access, requiring specialized techniques to ensure comprehensive coverage.

Varied Textures: Different materials (e.g., metal, glass) used in the helicopter’s construction can pose challenges in achieving uniform scan quality.

Introduction to Scantech NimbleTrack

The Scantech NimbleTrack is an advanced wireless 3D scanning system designed to capture high-precision 3D data of physical objects. Its portability and ease of use make it ideal for various applications, from industrial inspections to heritage preservation.

It is capable of capturing 3D data of different parts, intricate surfaces, and complex structures with ease. The system’s wireless functionality allows for unprecedented flexibility, enabling users to scan objects from any angle, even from challenging positions.

3D Scanning a Helicopter

The digitization process began with setting up the NimbleTrack system outdoors at the site where the Cobra helicopter was stationed.

NimbleTrack’s wireless and portable 3D scanning simplified the scanning process, even at elevated positions, including atop a six-foot ladder.

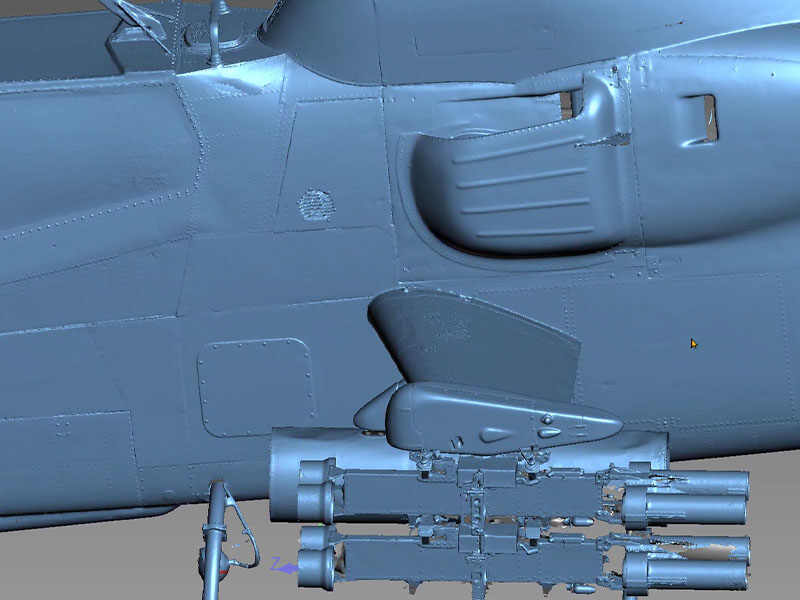

As the scanning commenced, the NimbleTrack showcased its ability to handle the helicopter’s intricate free-form shapes and complex structures, such as pipes and tubes.

The scanner’s high resolution and accuracy ensured that every detail, no matter how small, was captured. This level of precision is crucial for applications requiring detailed replicas or models for further analysis.

Advantages of NimbleTrack Optical 3D Measurement System

Wireless Freedom: The NimbleTrack system is fully wireless, eliminating the need for cables to power the instrument or transfer data. This feature allows for on-site measurements even in the absence of a power supply.

Compact and Portable: With a length of 57 cm and a total weight of 2.2 kg for the tracker and 1.3 kg for the scanner, NimbleTrack is lightweight and easy to carry and operate. Therefore, the engineer can capture data from hard-to-reach areas.

High Frame Rate: The system operates at a high frame rate of 120 FPS, ensuring fast and smooth scanning experiences.

Target-Free Scanning: NimbleTrack does not require targets for scanning, streamlining the measurement process.

Industrial-Grade Precision: The system achieves an accuracy of up to 0.025 mm and a maximum volumetric accuracy of 0.064 mm. It is capable of capturing intricate details of different parts with ease.

Robust Performance: Equipped with a powerful algorithm, NimbleTrack delivers efficient and reliable measurement experiences. It excels at capturing data from different surfaces.

Scan-to-CAD Model

Following the scanning process, the data was processed using 3D software designed for converting scan data into 3D CAD models. The data processing workflow included:

Importing Scan Data:

-The scanned data was imported into 3D software.

Cleaning and Refining:

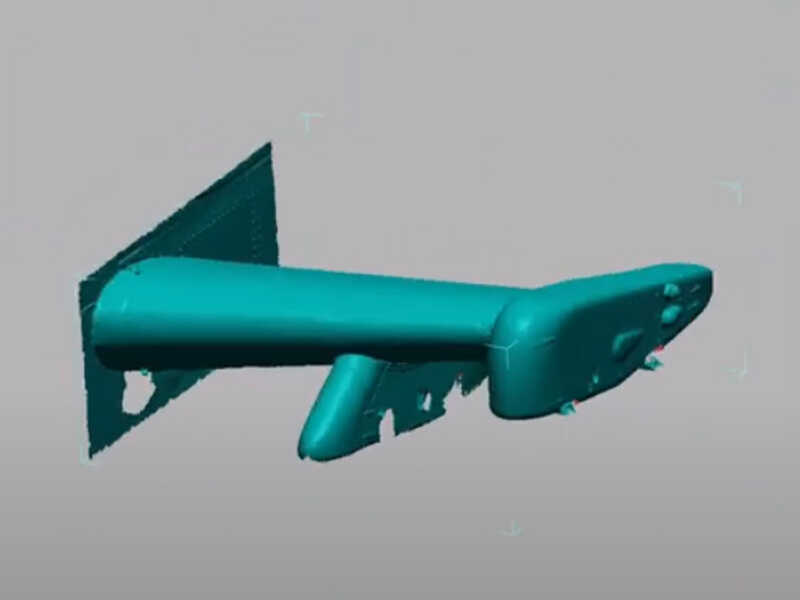

-Noise and unnecessary data points are removed from the point cloud.

-This step ensures a cleaner and more accurate representation of the scanned object.

Mesh Generation:

-The refined point cloud was converted into a mesh model.

-Meshes are essential for creating detailed digital models.

Solid Model Creation:

– A solid CAD model is generated using the mesh model.

-The solid model represents the object as a complete, editable 3D structure.

-It serves as a foundation for further design, analysis, or manufacturing processes.

Applications of 3D Scanning

3D scanning can contribute to various aspects from product development to maintenance, repair, and overhaul (MRO) of airplanes and helicopters.

Product Development

Advanced 3D scanning captures accurate data of aircraft components, allowing manufacturers to create rapid prototypes for testing and validation. It can also help recreate legacy parts or design new ones by capturing precise 3D models.

Besides that, 3D scanners can verify structural deformations, optimizing designs during research and development processes.

Inspection

3D scanning captures millions of data to inspect intricate components like turbines and engines. Non-contact measurement ensures accuracy without compromising delicate surfaces.

For example, Scantech’s handheld 3D laser scanners excel at inspecting sub-flush conditions of fasteners installed on aeroplane exteriors. These fasteners withstand extreme stress and are crucial for aircraft assembly.

MRO

In-service aircraft are scanned to identify hidden errors, deformations, and defects. 3D measurement technology ensures proper operation and passenger safety. Handheld 3D scanners provide non-contact measurements without damaging aircraft parts.

By scanning the entire surface of an aircraft, including complex geometries, technicians can identify structural issues, corrosion, or fatigue cracks. The high precision of 3D scans allows for early detection of problems, minimizing downtime and reducing the risk of in-flight failures.

Conclusion

The digitization of the Cobra helicopter demonstrated the capabilities of the Scantech NimbleTrack system in transforming a complex real-world object into a detailed digital model.

The portability and wireless functionality of the NimbleTrack, combined with the powerful data processing tools in 3D software, showcased a seamless workflow from scanning to model creation.

This case study underscores the revolutionary impact of 3D scanning technology in various fields.

The ability to capture intricate details and convert them into accurate digital models opens up numerous possibilities, from preserving historical artefacts to enhancing industrial design and manufacturing processes.

Discover the magic in action: Watch the webinar highlights and explore the capabilities of the Scantech NimbleTrack system further.

All Products

All Products

en

en