How to blaze a new trail in bathtub market by 3d scanning in aging society?

A comfortable bathtub can greatly improve the quality of life. However, the structural design of the ordinary bathtub is neither convenient nor safe for the elderly and the disabled. As the global aging becomes more and more serious, there is a growing demand for products for the elderly. At present, the sanitary ware market has introduced a barrier-free bathtub for the elderly. By changing the way the ordinary bathtub enters and exits, the comfortable seat cushion is added, which greatly enhances the comfort and safety during the bathing process. At the meanwhile, the problem is that the design of the barrier-free bathtub is not such simple. How to quickly generate the 3D model of the bathtub and invest in research and development has become the focus of domestic sanitary ware manufacturers.

Science time | Key Question

What is the scanning object this time?

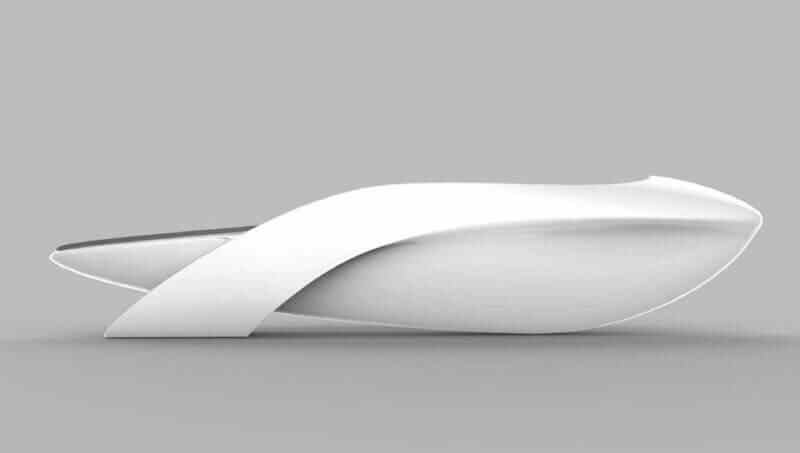

The barrier-free bathtub with its seats and cushions is designed for the elderly and those with reduced mobility. The bathtub is made of FRP.

What is the significance of measuring the three-dimensional data of bathtubs and seats?

The design of the barrier-free bathtub and seat is usually based on extensive development experience and professional experimental verification results. On the one hand, measuring the three-dimensional data of the bathroom can be used in product R&D design and quality inspection; on the other hand, reducing the design threshold of the barrier-free bathtub for the enterprise, facilitating the improvement on the existing bathtub appearance, and designing the product with the corporate brand characteristics.

What is the 3D measurement method for bathtubs and seats in the past? What is the problem?

Manual measurement, there are many problems of this measurement method obviously.

1.The space inside the bathtub is narrow, the measurement is difficult, time-consuming and laborious

2.The surface of the bathtub has many concave and convex surfaces, and the manual measurement accuracy is not enough.

3.It is difficult to obtain the complete 3D model of the whole bathtub by manual measurement, and 3D modeling and re-design are still needed when improvement is made.

What are the advantages of handheld 3D scanner measurement?

1.Measuring speed

2.Data integrity

3.Data accuracy

4.Operational flexibility

5.Reduce costs greatly.

SHOW TIME

Customer: Bathroom product manufacturer

Scanning object: Barrier free bathtub, 9 sub-parts

Scanning device: HSCAN331 handheld 3D scanner

Aim: Used for product reverse design and improvement

In the R&D process of the barrier-free bath, the ergonomic design of the seat cushion is particularly important, and requires a large amount of experimental data to support (the specific situation is similar to the development of the car seat). And many domestic manufacturers due to the limited development experience, R & D and manufacturing are generally carried out by reverse designing existing bathtub seats. This time, after many comparisons, the sanitary ware manufacturer finally chose HSCAN331 to participate in the design and development of new products for its barrier-free bathtub.

HSCAN series handheld 3D scanners perfectly meet customer needs in the following aspects:

1.3D data acquisition capability of complex surface features

2.Scans in tight spaces and the device can move freely

3.Non-contact measuring method, even if the surface of the bathtub is highly reflective, there is no need to spray powder

4.Lightweight, portable, and easy to operate

Solution:

After field investigation, Scantech found that accessible tubs that need to be scanned have complex surface features, and the precision of assembly between the components is very high.

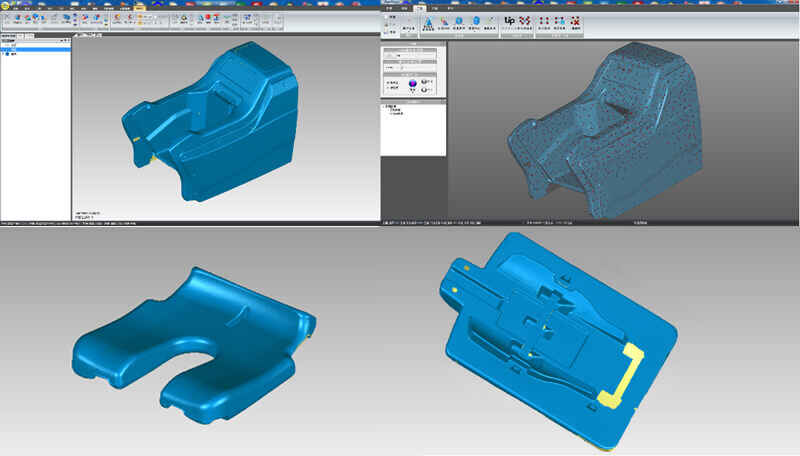

In view of the above situation, during the scanning process of using HSCAN 331, firstly, position the various parts of the bathtub, and then mark the points quickly to obtain the 3D data of each part of the bathtub. After the data is sampled and meshed, it is imported into the corresponding reverse modeling software for redesign and improvement.

Scanning object:

Scanning object: Barrier-free bathtub and its components

Device & Model: HSCAN331 Handheld 3D scanner

3D scanning results:

3D stl data

3D scanning working time:

It takes 20 minutes to mark points. (The total time of Bathtub + 9 parts)

It takes 40 minutes to scan. (The total time of Bathtub + 9 parts)

It takes 20 minutes to data post processing.

80 minutes in total.

The HSCAN331 handheld 3D scanner can quickly and accurately obtain the 3D data of the various components of the barrier-free bathtub. After the block processing, the accurate surface size is obtained, and the scanned data is imported into the reverse modeling software, which provides a more accurate and convenient data source for the later reverse and improvement, and also greatly shortens the time for bathtub design development.

All Products

All Products

en

en