1.The problem of customer

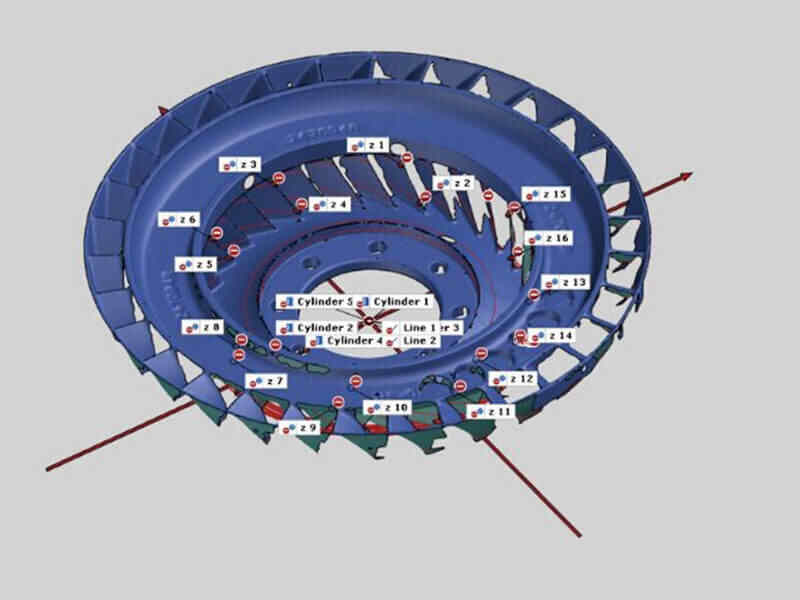

Turbine is a fan in the engine of a car or airplane that improves the performance of the engine by blowing fuel vapor into the engine using exhaust gas. A turbine is a rotary power machine that converts the energy of a flowing medium into mechanical work. It is one of the main components of aero engines, gas turbines and steam turbines.

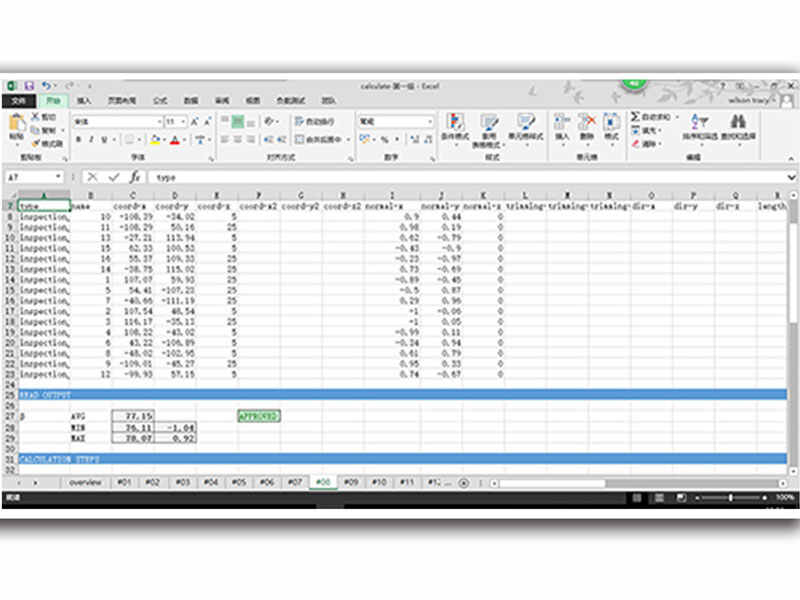

Customers of domestic machinery factories need to issue inspection reports because they accept overseas orders, and the traditional three-coordinate measurement efficiency is low, which seriously affects the production efficiency of enterprise work manufacturing, only a bit of the products are exported to overseas.

All Products

All Products

en

en