I. Customers’ Requirements

Customers need to detect and repair the car damages after collision, however, the curved surface of the car causes that traditional detection method can’t accurately and quickly collect the data. Therefore, they want to optimize the detection method to reduce workload and working time.

II. ScanTech unique solution

ScanTech Co., Ltd (Hangzhou, China) specially developed a type of handheld 3D laser scanner— HSCAN331 3D scanner. It can fast detect and correct the deviation based on standard data without stickers and powder spray.

Required 3D scanner: HSCAN331

Scanner working time:

2 minutes for marker stickers

5 minutes for 3D data scanning

5 minutes for data contrast detection

III. Scan data & results

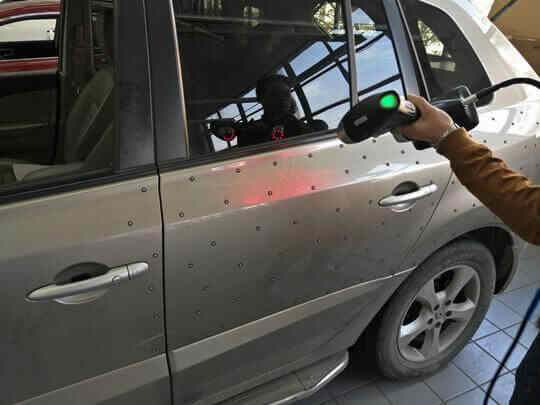

1.Scan the work environment

▲3D scanning the damaged car

▲3D scanning the standard car

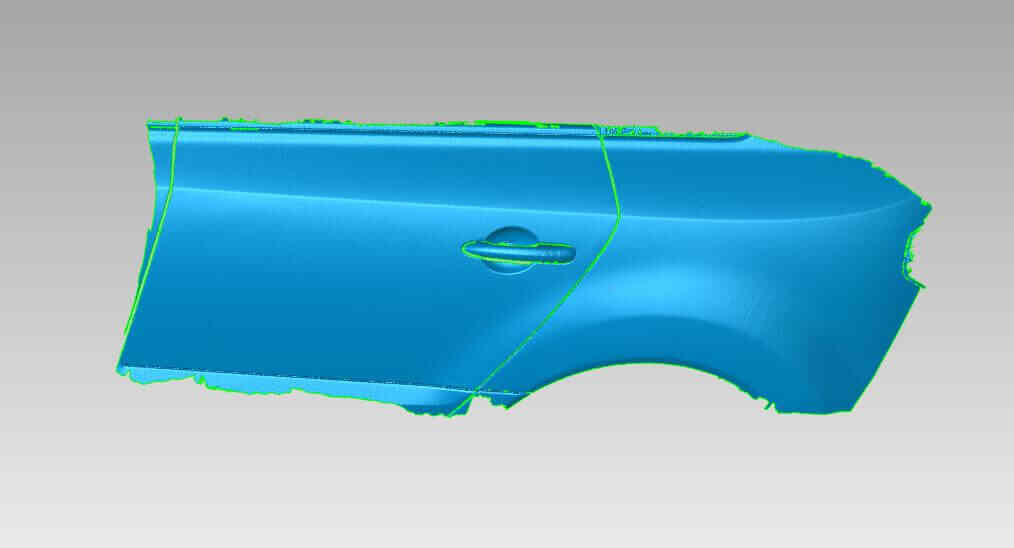

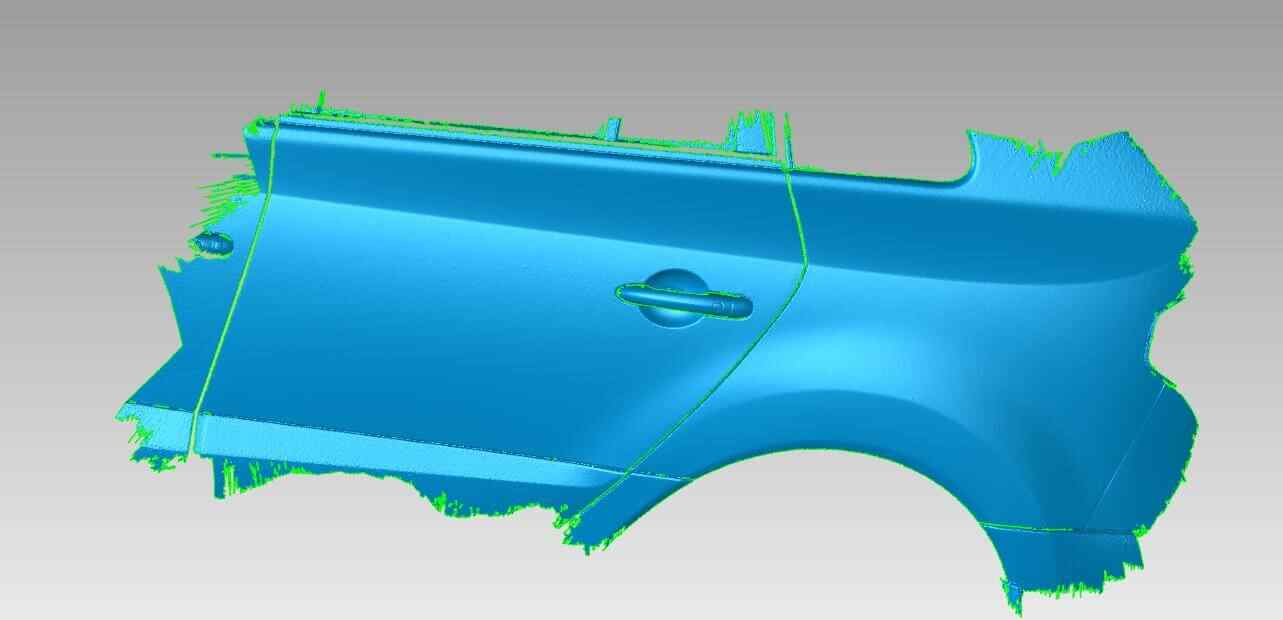

2. Scan data

▲Stl 3D data of damaged car

▲Stl 3D data of the standard car

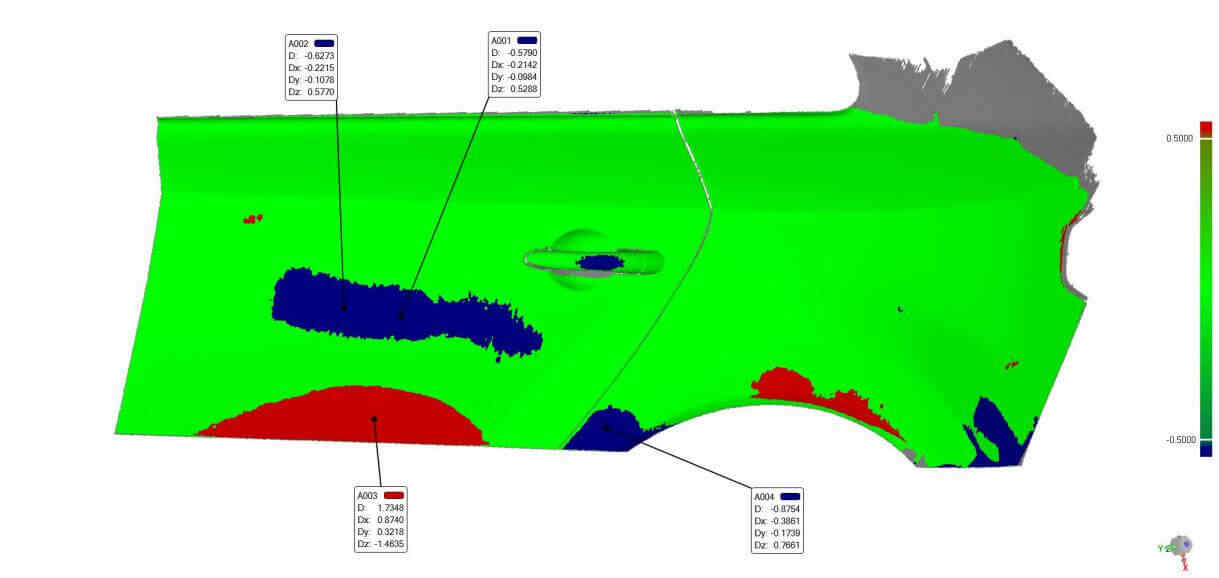

3. Color map

From the above information, we can easily draw a conclusion that handheld 3D laser scanner HSCAN 311 quickly and accurately obtained the data of damaged car. It detected the deviation between damaged and standard car, this is to provide more precise and convenient solutions for car maintenance.

All Products

All Products

en

en