Summary

The handheld 3D scanner of Scantech collects the complex 3D shape data of the furniture efficiently, quickly and accurately, which greatly simplifies the design and transformation process of the furniture carving style, greatly liberates the manpower of the furniture engraving process, and greatly improves the production efficiency of the furniture.

The customer of Scantech: A furniture manufacturer

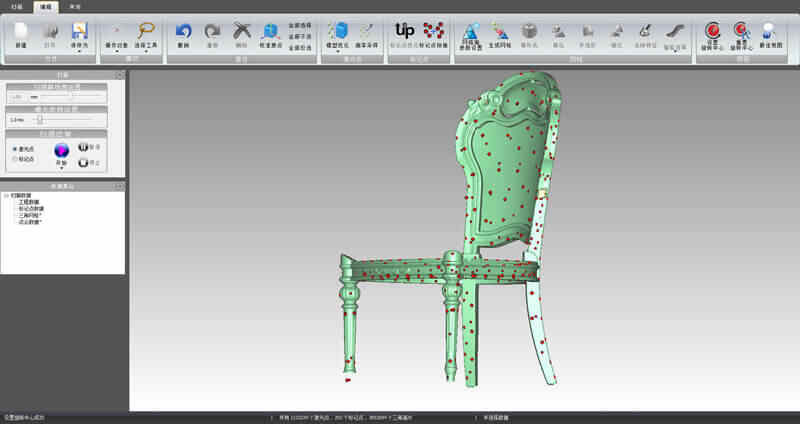

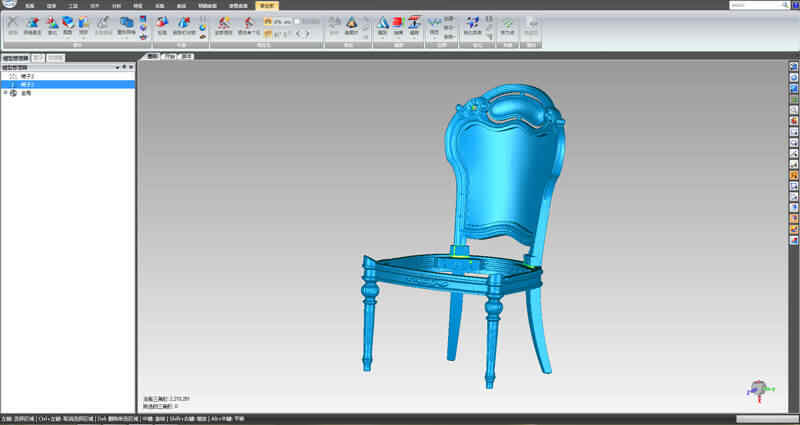

Scanning object: Solid wood furniture dining chair with carving

Scanning requirement: To obtain the accurate 3d data of the carved patterns and shapes of the furniture to ensure the automatic production can reach the technical level of the old carpenter.

Aim: Solve the problem of high-level carpenter resources scarcity, and the problem of machine engraving Distortion dullness stagnation.

The status of industry

As we all know, the quality of hand-carving of solid wood furniture depends on the carpenter’s carving level, and a skilled old carpenter in the furniture industry is “hard to find” and the cost is extremely high, which greatly increases the process cost of solid wood furniture manufacturers and greatly reduces the production efficiency.

Therefore, many furniture manufacturers now use machine engraving, mainly used for positive mapping of furniture, digital editing of furniture 3D design drawings, and automated production through computer with engraving machine.

However, machine engraving is only suitable for engraving simple regular graphics. For complex, multi-curved graphics engraving, there are inevitably shortcomings of stereotype, simplicity, and poor layering; it is very difficult to design complex engraving, and it is time consuming, also the accuracy and precision can’t be guaranteed.

It can be seen that both manual and machine engraving have advantages, is there a solution that offers the best of both worlds?

Obviously, handheld 3D scanner of Scantech is the best choice to solve this problem! Next, let’s look at how 3D solves the problem of engraving process and liberate the labor to reduce production costs of the furniture manufacturers.

All Products

All Products

en

en