Infrastructure is related to the sustainable development of a country or region, and the excavator is regarded as one of the most important construction tools on infrastructure projects. Therefore, the performance of excavators deserves our attention.

Why is 3D inspection vital to excavator stick?

Stick is an indispensable component that frequently moves, working through shaft hole. If the shaft hole is unqualified in design, it will cause the stick to sway and decreases work efficiency. Hence, strictly quality control of shaft hole is inevitable. Normal handheld 3D scanner, however, can’t reach the high speed and precision.

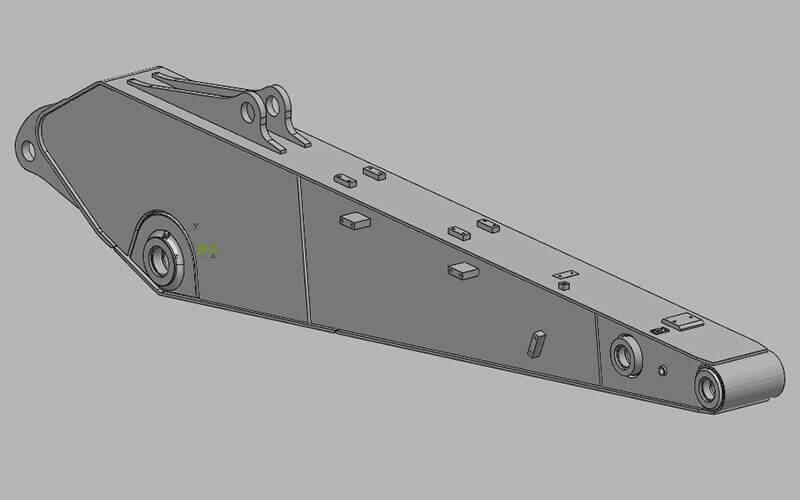

ScanTech 3D solution

ScanTech TrackScan 3D scanner can easily detect the excavator stick length in 10 meters, and quickly collect accurate 3D data, using unique tracking technology and getting rid of markers. When it combines with TrackProbe light pen, it can also achieve contact measurement on stick length in15 meters, and easier to get 3D data of shaft hole.

1. Scanning process

Stick size:

- Length in 3000mm

- Width in 650mm

Shaft hole 3D inspection with TrackProbe light pen

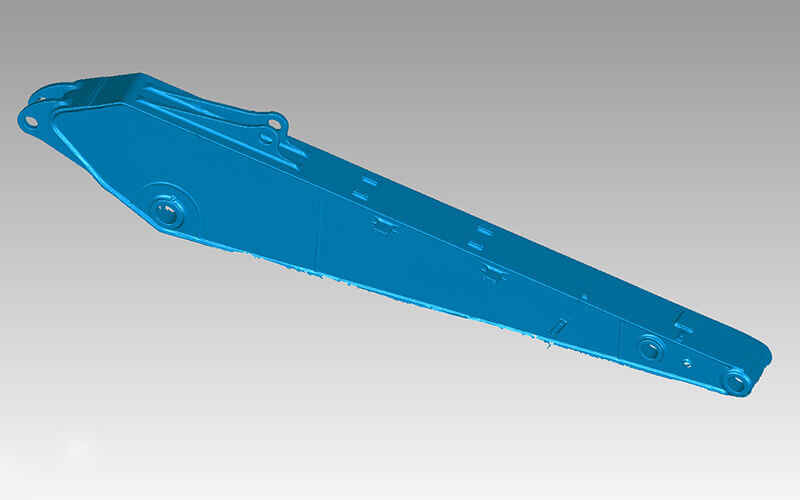

2. Obtain accurate 3D stl data

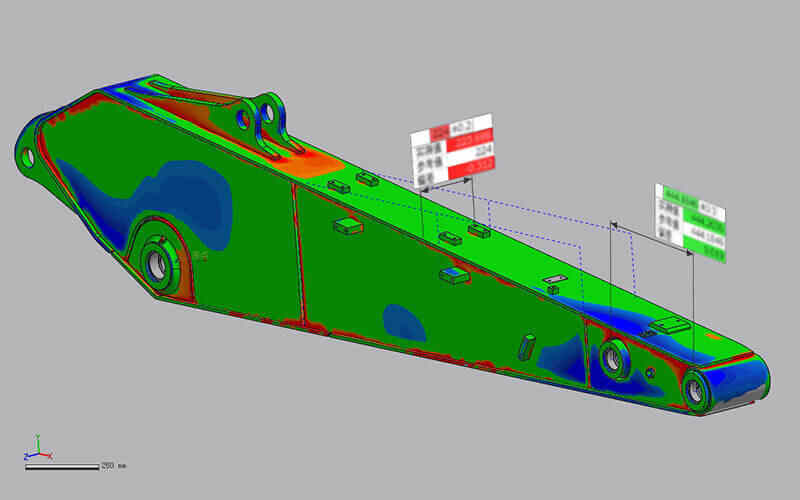

3. Contrast detect with original CAD data

4. Get specific deviation data

5. Time cost

ScanTech TrackScan 3D scanner benefits from years of technology experience in industrial measurement and owns high military quality, so it contributes a lot to machinery manufacturing post-processing correction.

All Products

All Products

en

en