Oil drilling is a complex and challenging process that requires high-quality and customized drill bits. Polycrystalline diamond compact (PDC) bits are widely used in the oil field.

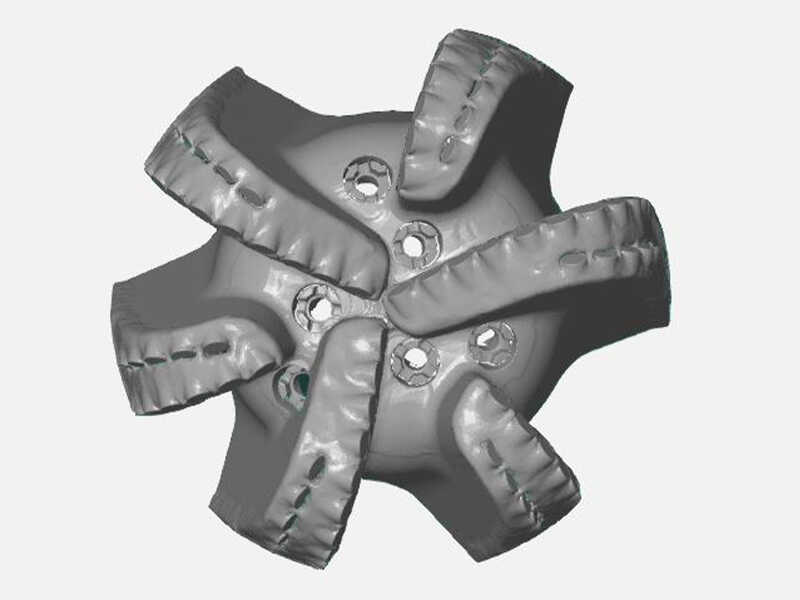

Features such as cutter types, cutter layout, and blade geometry are constantly being optimized and enhanced to deliver value and reduce drilling costs.

The PDC bits used in oil drilling are typically composed of natural diamond inlays, featuring diamond particles arranged in a spiral or radial fashion on the surface of the drill bit.

A series of fluid courses are also arranged on the surface of the bit, which serve to cool the diamond by flushing it with fluid flowing out from the nozzle. To ensure the drill bit operates efficiently, the shape of the bit, position of diamond inlay, and position of nozzles must be inspected precisely.

The critical distribution of courses on the bit varies depending on the type of rock being drilled. The dimension and geometry of existing bits can serve as guidance to properly design new products.

In this blog, we will introduce how to use a portable 3D scanner SIMSCAN for oil drill bit inspection and product development, and how it can improve the efficiency and accuracy of the process.

About the Customer

DEEP BIT has over seventeen years of experience supplying quality products and services to customers worldwide. In China, DEEP BIT holds the leading market share and top performance position for almost all Onshore and Offshore applications.

The Challenge of Inspecting for Oil Drill Bit

It is made of alloy steel and diamond materials using sophisticated machining and embedding techniques. The drill bit possesses a unique design, featuring a golden surface that reflects light and a black surface that absorbs light.

Previously, the company used traditional measurement methods to measure the PDC bits, which are inefficient. For example, those machines were bulky and inconvenient to transport to the drilling site. Moreover, finding a suitable cast iron platform to secure the machine posed further inconvenience.

The company was looking for a new measurement method to accelerate the inspection workflow. High-tech 3D scanning comes into the mind. The 3D scanner they need has to be portable, efficient, and precise.

Besides that, it needs to be highly efficient to scan both dark and reflective surfaces and operate outdoors under direct sunlight.

The SIMSCAN 30 portable 3D scanner offers rapid scanning speed, which is also capable of scanning bright and dark surfaces, eliminating the need for powder spraying.

It boasts a compact and lightweight design, delivers remarkable accuracy, and facilitates on-site scanning with comprehensive scanning data.

How to Inspect Bit by 3D Scanning

The customer needed to inspect the shape of the drill bit body and the position of the diamond inlay to ensure its quality.

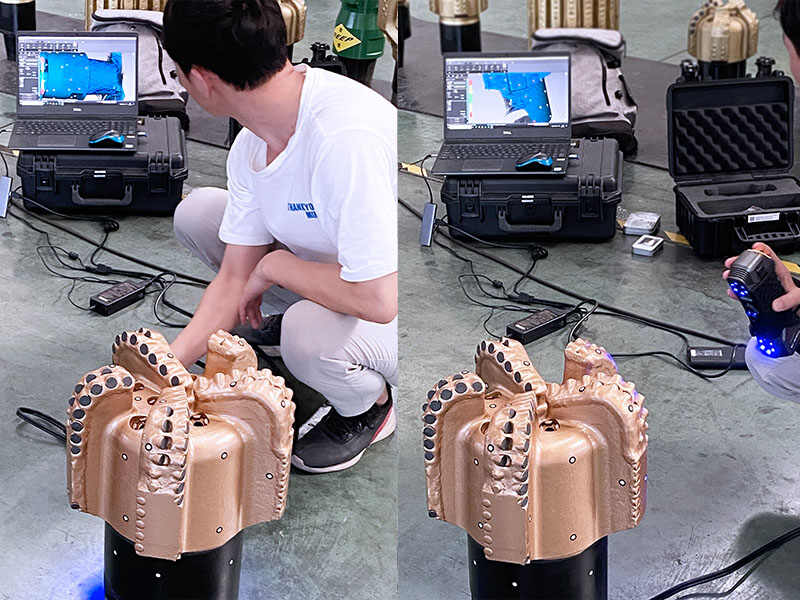

By utilizing the SIMSCAN 30 portable 3D scanner, engineer navigated the 3D scanning process with ease. It took the engineer 2 minutes to stick targets, 30 seconds to calibrate, 2 minutes to 3D scan, and 5 minutes to generate report.

The 3D scanner scanned the drill bit from multiple angles and distances, and automatically stitch the scan data together. The 3D scanner scanned both the golden and black surfaces of the drill bit without any difficulty. It can also scan outdoors under direct sunlight without any interference.

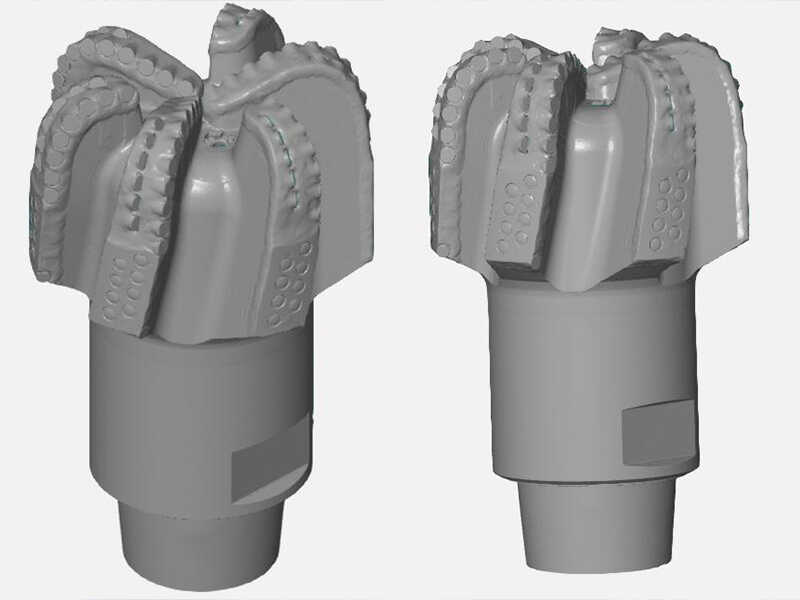

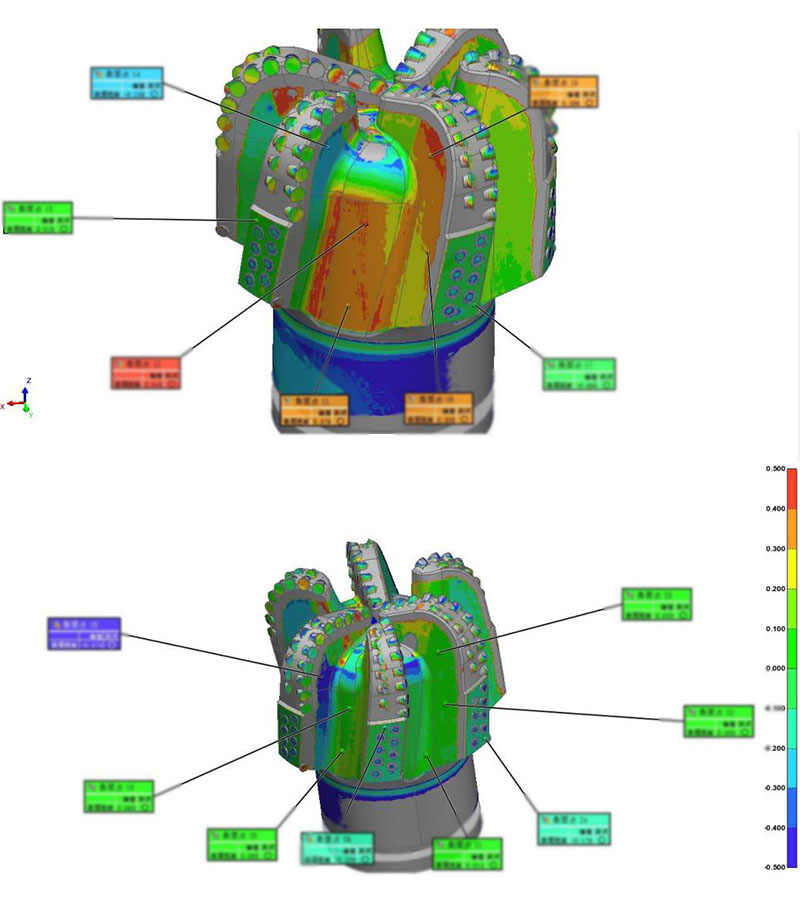

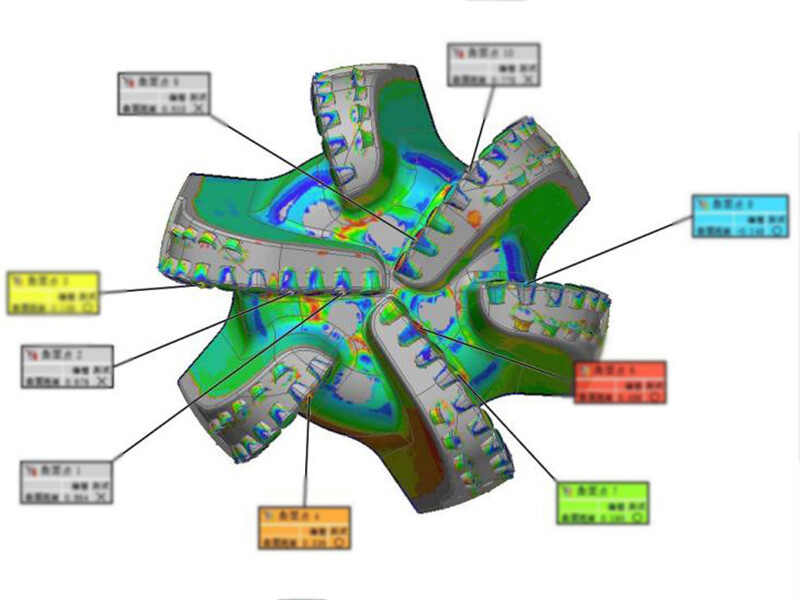

The scanning data was then compared with the original digital model within the 3D software, allowing for the identification of any deviations from the intended design. Through further analysis using a color map, defects in the drill bit and diamond position were identified visually.

Advantages of 3D Solution Powered by SIMSCAN

Suitable for Measuring Holes and Courses

SIMSCAN is a handheld 3D scanner that can measure hard-to-reach areas. It has a short camera distance of about 130 mm, which gives it a sharp view angle. This means that it can scan narrow spaces such as holes and grooves more easily.

High Adaptability to Black and Reflective Surfaces

SIMSCAN can adapt to black and reflective surfaces. Due to its blue laser with high anti-interference ability and sophisticated algorithm, it can capture every detail of objects and create 3D models quickly without spraying powder on the part.

Efficient and Precise Measurement

SIMSCAN is small, simple to use, but powerful. It can measure and inspect 3D objects with ease. It has a high measurement rate of up to 2.8 million MPS, which makes 3D digitization smooth. It can also achieve a high measurement accuracy of up to 0.020 mm.

Intuitive Data Analysis

The SIMSCAN 3D scanner works with the ScanViewer 3D software. It can align data in different ways, such as best-fit, datum-based, and feature-based alignment. The software also shows the inspection results in a color map that makes it easy to see the surface and point deviations.

Oil drilling requires a wide variety of drill bits, each with different specifications, to suit the unique formations encountered. Portable 3D scanner SIMSCAN can quickly and precisely scan the samples of these drill bits and generate 3D models that can be modified and analyzed in CAD software.

This allows customers to improve the design, performance, and durability of their existing drill bits. 3D scanning also helps to speed up and lower the cost of prototyping by enabling the use of 3D printing or CNC machining to produce the drill bits.

Conclusion

The portable 3D scanner is a powerful and convenient tool for oil drill bit inspection and product development. It can scan the the geometry of drill bit and diamond position with high accuracy and speed, and provide comprehensive visual data for quality control and product development.

The portable 3D scanner can also scan outdoors under direct sunlight, and handle bright and dark surfaces without any problem. The portable 3D scanner can improve the efficiency and accuracy of the oil drilling process, and help customers achieve better results.

All Products

All Products

en

en