Nowadays, the automobile has already turned into a consumption-grade product that most of us can afford.

After the new listing, auto parts manufacturers must know the accurate 3D data of automobile interiors very timely, which helps them finish the product development faster and keep stay ahead of their competitors.

What do auto parts makers need?

It is not going too far at all to describe the automobile industry as “changing with each passing day and month”. Pursuing private customization becomes a trend for more car owners.

With the development of technology, 3D scanners turn out to be a great problem solver in automobile manufacturing. Compared with 3D scanning, traditional manual measurement has obvious shortcomings for auto parts manufacturers.

Manual measurement

Disadvantages of traditional manual measurement:

- Insufficient data acquisition

- Can’t measure the curved surface of automobile interior

- Measurement accuracy is greatly influenced by the practical experience of the operator

- Low work efficiency and time-consuming

- Long product time-to-market

ScanTech 3D Solution

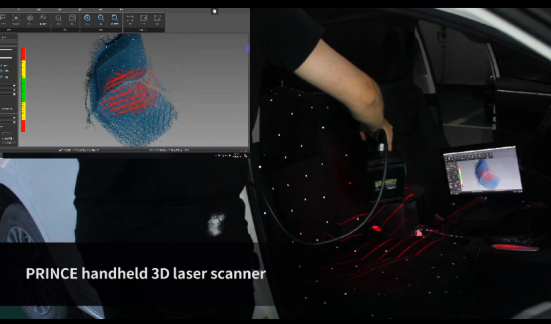

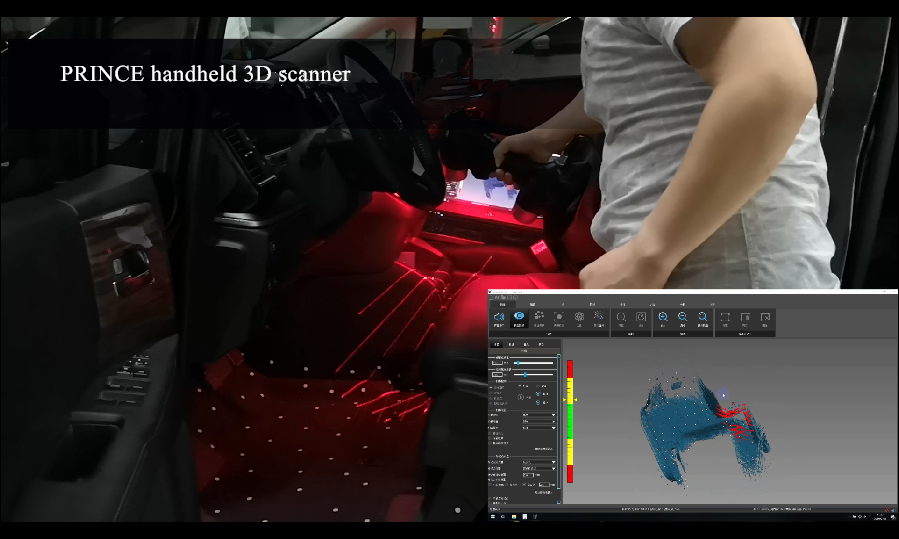

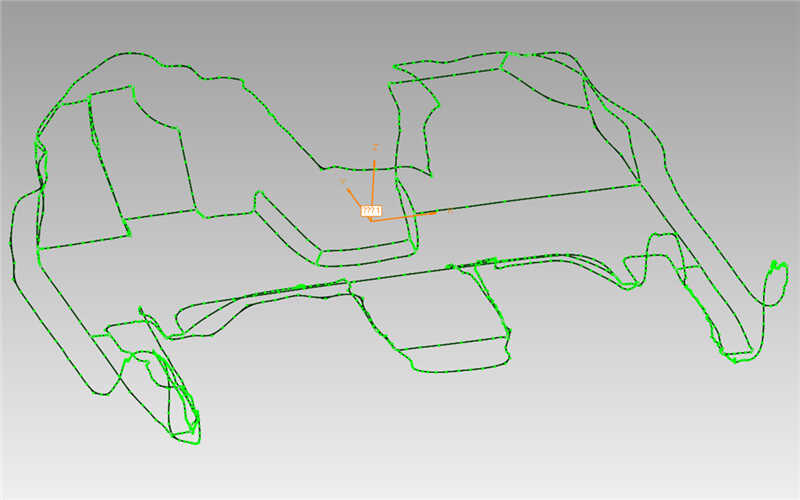

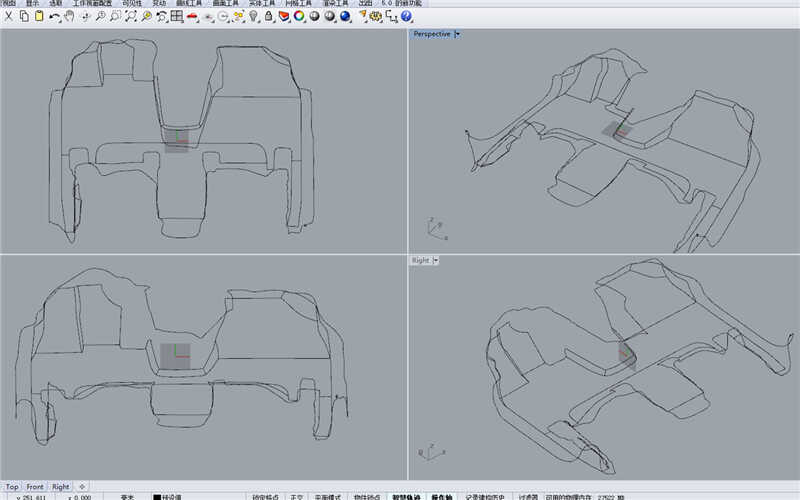

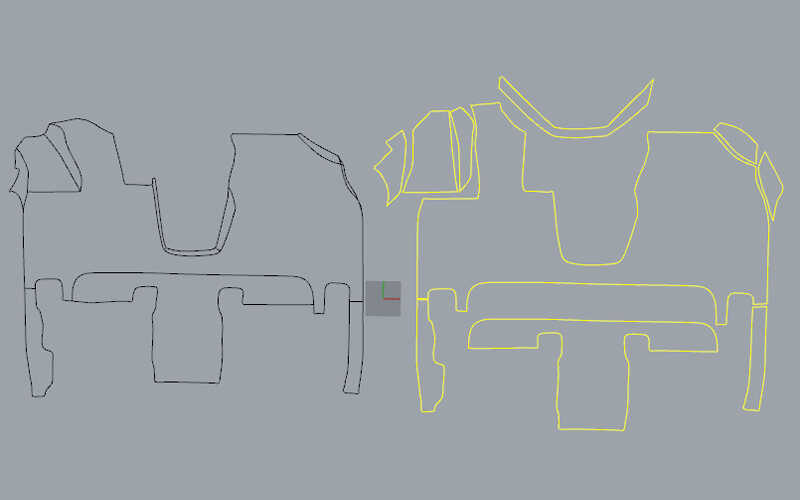

ScanTech 3D scanners make the best of their strengths in various applications, such as aerospace and automobile. Our PRINCE 3D scanner focuses on improving measurement accuracy and streamlining operation flows.

In the following two cases, PRINCE 3D scanner makes the best of its strengths:

- Rapidly get the 3D data of automobile interiors by 480,000 measurements/s in red laser mode.

- Digital drawing collection and archiving to avoid data loss.

- Lower the requirements for measurement operators even for a new beginner, greatly enhancing the work efficiency of manufacturers.

All Products

All Products

en

en

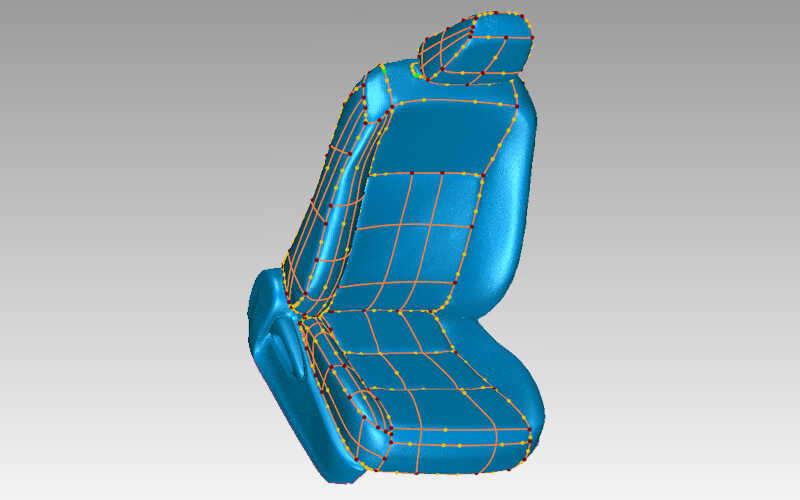

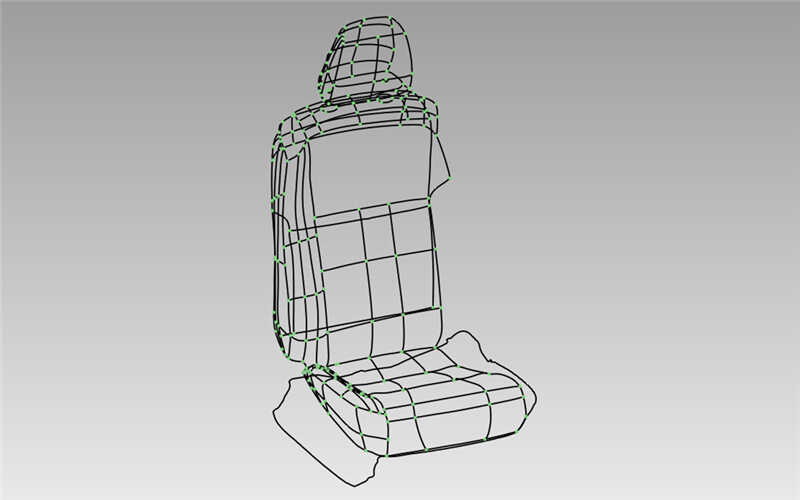

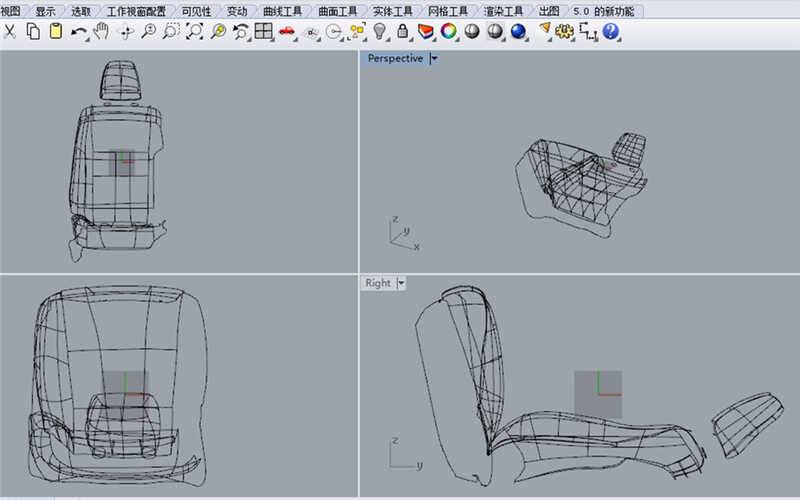

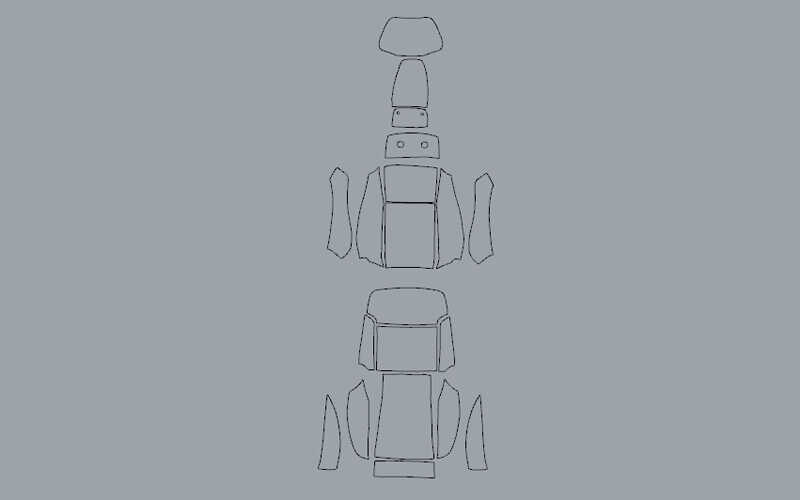

3D scanning of auto seat

3D scanning of auto seat