The built-in photogrammetry system improves volumetric accuracy up to 0.020 mm/m and accuracy up to 0.020 mm. AXE-B11 offers professional 3D scanning for large-volumes without an extra device.

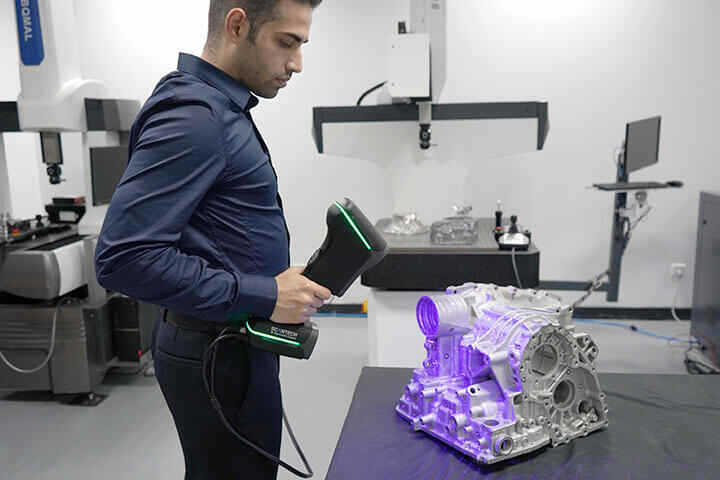

AXE-B11 3D Scanner

AXE-B11 3D scanner opens up a new 3D experience to large-scale 3D measurement without an extra device.

The 11 crossed blue lasers greatly increase the measurement rate to 1,300,000 measurements/s. And the single blue laser line can rapidly obtain 3D data of deep hole and inaccessible positions of complex objects.

The built-in photogrammetry function can scan large-scale objects with ultra-high accuracy individually (volumetric accuracy up to 0.020 mm/m and accuracy up to 0.020 mm).

The ultra-fast speed facilitates the process of measuring large volumes by 1,300,000 measurements/s, saving numerous working time and labor cost.

With 550 mm × 600 mm of scan area, it only needs very few markers to finish the scanning.

Due to 11 crossed blue lasers + 1 extra blue laser line, AXE-B11 supports high-efficiency mode for large-scale scanning and single line scanning mode meets special requirements, such as deep hole and dead angle inspection.

AXE-B11 3D scanner fulfills different measurement demands by freely matching with the accurate reference bar, Helpers engineer kit, etc.

Ready To Get Started?

Rebuild our 3D world with the most advanced 3D scanning system available.

Technical Specifications

Technical specification

| Type | AXE-B11 | |

|---|---|---|

| Laser source | 11 blue laser crosses + 1 extra blue laser line | |

| Deep hole scanning | 1 extra blue laser line | |

| Accuracy(1) | Up to 0.020 mm | |

| Measurement rate | Up to 1,300,000 measurements/s | |

| Scanning area | Up to 550 mm × 600 mm | |

| Scanning area (photogrammetry) | 2500 mm × 3000 mm | |

| Laser class | CLASS Ⅱ(eye-safe) | |

| Resolution | 0.025 mm | |

| Volumetric accuracy (without extra device)(2) |

Work alone | 0.020mm+0.035mm/m |

| Work with 1m reference bar | 0.020mm+0.020mm/m | |

| Work with MSCAN-L15 | 0.020mm+0.012mm/m | |

| Stand-off distance | 300 mm | |

| Depth of field | 500 mm | |

| Depth of field (photogrammetry) | 2500 mm | |

| Output formats | .stl, .ply, .obj, .igs, wrl, .xyz, .dae, .fbx, .ma, .asc or customized | |

| Operating temperature range | -10℃ – 40℃ | |

| Interface mode | USB 3.0 | |

| Patents | CN204329903U, CN104501740B, CN104165600B, CN204988183U, CN204854633U, CN204944431U, CN204902788U, CN105068384B, CN105049664B, CN204902784U, CN204963812U, CN204902785U, CN204902790U, CN106403845B, CN209197685U, CN209263911U, CN206905709U, CN107202554B, US20200225030A1, US10309770B2, KR102096806B1, KR102209255B1, US10914576B2, EP3392831A4 | |

(1) ISO 17025 accredited: Based on VDI/VDE 2634 Part 3 standard and JJF 1951 specification, probing error (size) (PS) performance is evaluated.

(2) ISO 17025 accredited: Based on VDI/VDE 2634 Part3 standard and JJF 1951 specification, sphere spacing error (SD) performance is evaluated.

Compare Products

Compare Products

All Products

All Products