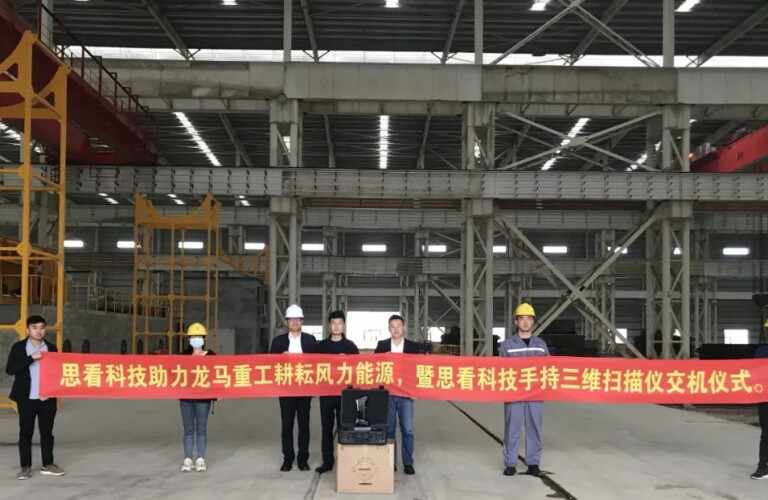

ScanTech 3D Scanning Technology Applied in Wind Power Development

Recently at a hand-over ceremony, SCANTECH delivered the KSCAN-Magic composite 3D scanner to Guangdong Longma Group for quality control of large-sized wind power casting.

Longma is a leading national supplier of castings for wind power facilities and mainly manufactures big machining parts such as wheel hubs, bases, fixed axles, rotating shaft, cases and blades. To measure the 3D size of dies and blanks and confirm data such as machining allowance and deformation, Longma chose ScanTech’s KSCAN-Magic 3D scanner after cautious consideration.

Castings for wind power facilities are large in size varying from a few to dozens of meters, which has a strict requirement of the 3D scanner in efficiency and accuracy.

Before that, Longma also used other brands, but their 3D scanners are so cumbersome that two persons were needed to operate. Those 3D scanners are not suitable for products with internal holes and various angles, costing a large amount of time and labor.

The KSCAN-Magic 3D scanner has the following advantages to inspect castings for wind power facilities:

- The KSCAN-Magic 3D Scanner features a built-in photogrammetry system and the global pioneering infrared laser scanning technology that can scan an area up to 1440mm × 860mm for 1,350,000 measurements per second at accuracy of 0.020mm.

- Such greataccuracy and efficiency make it perfect for large castings. Longma previously spent about 5 hours toinspect a 6MW wheel hub, but now it only takes 2.5 hours, marking a significant progress of efficiency.

The handheld KSCAN-Magic 3D Scanner is portable with a size of approximately 315mm x 165mm x 106mm and the weight of 0.95kg. It can be held by one operator when working.

SCANTECH offers comprehensive training and services. A sample 3d scanner was provided to Longma before the formal delivery. Technicians will be sent to give full-procedure guidance and training in order to guarantee the production progress of the customer and the subsequent application.

(For confidentiality, this picture is just for reference)

The KSCAN-Magic series 3D scanner ensure high-quality 3D inspection of castings for wind power facilities due to the high accuracy, performance and complete after-sales services. Looking forward, SCANTECH will continue to develop technologies and offer efficient and accurate 3D digital solutions for more customers.

For more cases about large project, please read below:

All Products

All Products

en

en