12 Minutes 3D Scanning for Automotive Steering Gear?

What does the industry need?

Automotive steering gear fixes and protects rack and input shaft, but also limits rack stroke, the importance of it does not allow to forming manufacturing deviations, or that will affect our personal safety. Hence, it requires high accuracy for quality inspection.

ScanTech 3D scanner VS normal inspection devices

ScanTech HSCAN771 handheld 3D laser scanner

● User-friendly

● 480,000 measures/s without powder spray

● Comprehensive 3D inspection

● Quickly get accurate 3D data

● Generate deviations against the data model

Demerits of normal inspection devices

CMM:

● Complicated operation steps

● Point-point measurement

● Fail to get complete dada

Photogrammetry 3D scanners

● Need powder spray

● Inconvenient to clear in post-treatment

ScanTech Solution

Product

ScanTech HSCAN771 handheld 3D laser scanner

Time cost

● Attaching stickers: 3 minutes

● 3D scanning: 4 minutes

● Inspection report: 5 minutes

3D scanning process

Stickers on automotive steer gear

HSCAN771 3D scanning on automotive steer gear

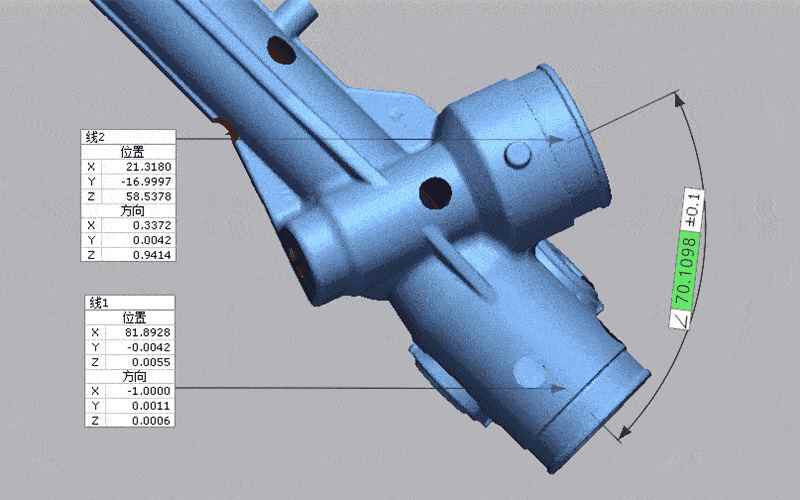

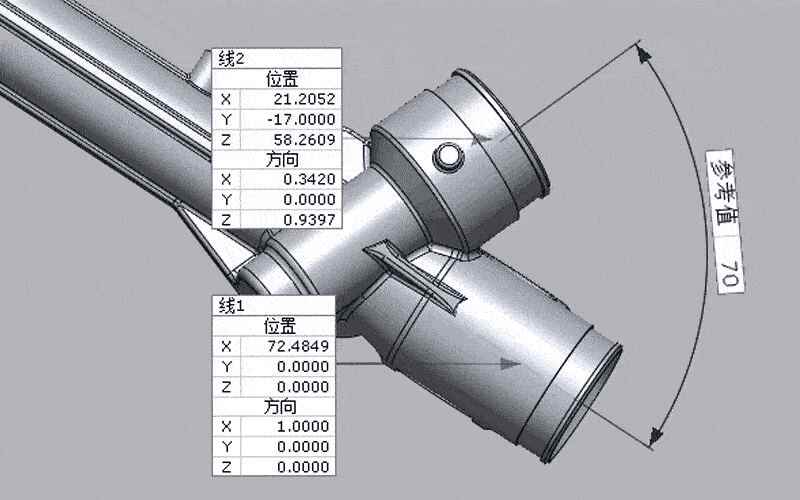

3D STL data

Data model

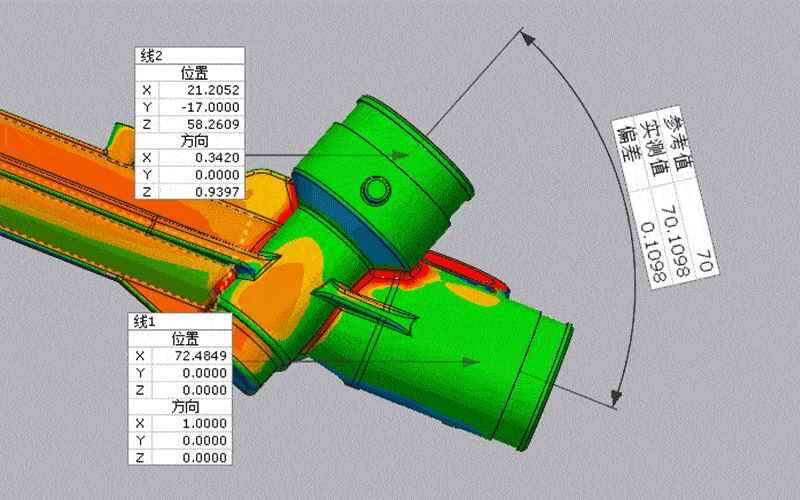

Color map & deviations

Apparently, 3D inspection in automotive industry is very significant, and ScanTech HSCAN 3D scanner is definitely a great helper of automobile steer gear. We will work harder for automobile manufacturers and make 3D scanning widely available in this field.

All Products

All Products

en

en