Fake or Real? 3D Scanning of Cultural Relics

With the continuous development of science and technology, the identification and inspection of cultural relics have had a big breakthrough. Before that, what kind of problems did our inspectors confront?

Difficulties of cultural relics appraisal

● The traditional method takes considerable time and labor.

● Cultural relics may be replaced and damaged during borrowing and exhibition.

● The identification work-flows is intricate and complicated.

However, nowadays, 3D scanning technology brings us an innovative way to handle these problems. 3D scanning of cultural relics has obvious advantages in precise data acquisition and effective work efficiency.

What does the customer need?

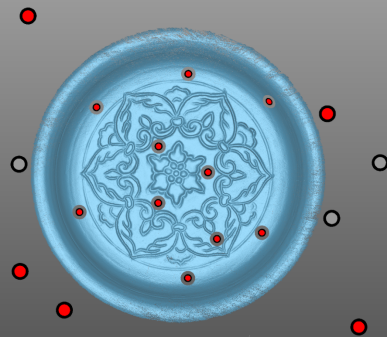

The ceramic relic is relatively fragile. It has various patterns and complex structures.

China Society of Inspection and Quarantine ( CSIQ) demands as follows:

● Get the 3D data of it and archive the data by 3D scanning.

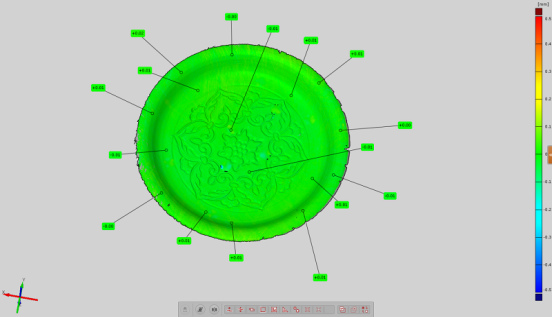

● Perform a second scanning of the returned ceramic relic.

● Compare the new 3D data with its original data so as to judge the authenticity.

Structured 3D scanner VS Handheld 3D scanner

CSIQ is used to measure the ceramic relics by the structured 3D scanner, but this method indeed reflects some shortcomings:

● Shiny surface needs to be powder sprayed, which is easy to damage the cultural relics and is hard to clean up post-process.

● The structured 3D scanner requires a high environment and light.

● The preliminary work is time-consuming and low efficient.

As technology improved, handheld 3D scanners came out and eliminated the above worries:

● No powder spray

● Insensitive to environment and light

● Fast measurement speed

● High-precision data acquisition

● User-friendly

Case analysis

Ceramic relic undergoes molding and calcination during production, and deformation is inevitable. Therefore, there will be some differences between fake and genuine artifacts in shape.

Such differences are indistinguishable from the naked eye. Nevertheless, a 3D laser scanner contributes to performing accurate data for 3D inspection.

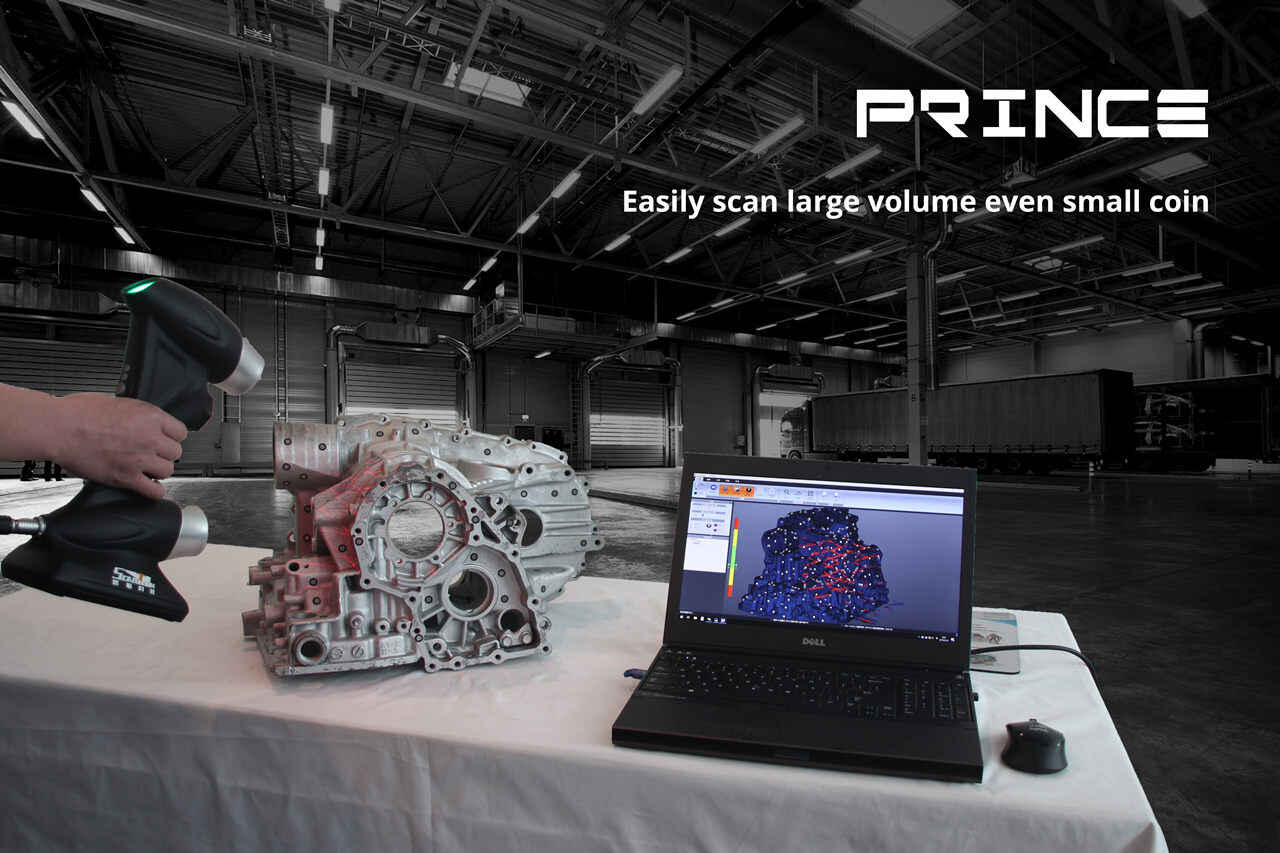

To safely scan the ceramic relic without any damage, we decide to use PRINCE 3D laser scanner to finish the whole 3D measurement.

PRINCE 3D scanner adopts red and blue laser scan modes: the red laser mode can get the point data of the ceramic relic with a fast speed of 480,000 measurements/s, and the blue laser mode obtains the ultra details with a resolution of 0.02 mm.

Besides, the PRINCE 3D scanners can be operated in any environment, which greatly optimizes workflow. Most importantly, to protect the integrity of the relics, the PRINCE 3D scanner can conduct scanning without powder spray.

The accurate 3D data of the ceramic relic can be archived and used for inspection. Moreover, the scanned 3D data can accurately identify genuine relics and imitation products. Therefore, a 3D scanner provides a reliable identification basis for inspection professionals.

PRINCE handheld 3D scanner is not only applied to identify ceramic artifacts but also to recognize ancient inscription and inspect ancient jade and bronzes.

Moreover, the PRINCE 3D scanner helps scan masterpieces and build a database. Hence, 3D scanning technology enhances the value of works and supplements data materials, which gives support for later research.

All Products

All Products

en

en