What comes to your mind when criminal forensics and evidence identification are mentioned?

Is it the scene where police officers take photographs at the crime scene and identify the position of the victim?

Or is it like what is described in TV dramas where forensic experts conduct various tests before eventually finding the key evidence to crack the case?

It is a common impression that forensic analysis is a very tedious job entailing evidence collection, identification and discrimination using various instruments, evidence preservation and archive. All these procedures are time and labor consuming and may even result in loss of evidence in case of misoperations.

3D scanning technology stands to alleviate some of the burdens of these procedures.

In areas of material evidence management, footprint analysis, traumatic identification and auricular injuries identification, 3D scanning technology proves to have a great potential for application.

Case 1 Material Evidence Management

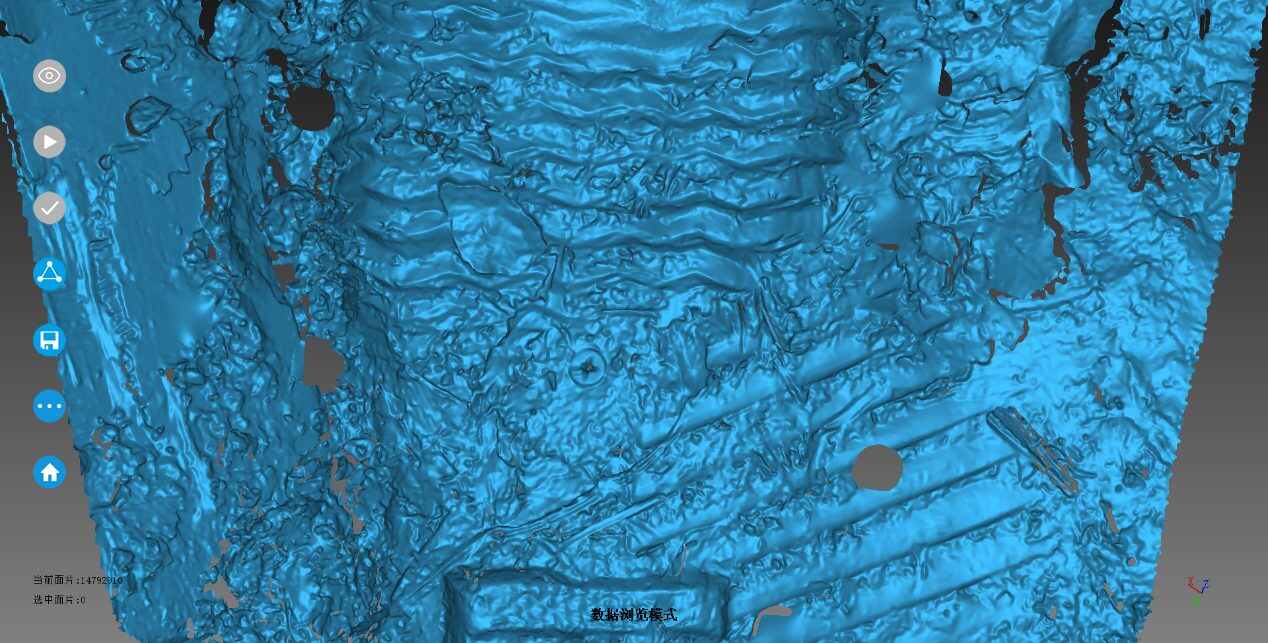

Recently, Jiangxing courts have pioneered the use of digital intelligent material evidence management mode. Using artificial intelligence (AI), judicial blockchain, 3D data and modeling and other technologies, the court constructed a material evidence management platform where 3D scanning modeling becomes a new approach to collection and storage of material evidence data. SCANTECH’s 3DeVOK color 3D scanner and PRINCE handheld 3D scanner were presented in the technical demonstration concerning the construction of the system.

Recent years have witnessed frequent occurrences of intellectual property. Compared with regular civil cases, intellectual property cases tend to involve large amounts of material evidence, and the accumulation of large bodies of evidence over time could easily overwhelm evidence storage warehouses.

Digital intelligent material evidence management can effectively tackle the pain points relating to evidence storage, management and search. SCANTECH 3D scanners can be applied to generate 3D models of material evidence, and material evidence can then be uploaded onto the intelligent material evidence management platform, allowing litigants to take back their material evidence for preservation and present them later if needed.

SCANTECH 3D laser scanners have significant advantages in terms of material evidence scanning: high accuracy (maximum accuracy 0.02mm) and high fineness (maximum resolution 0.010 mm) of data that can be easily obtained without the need to perform surface treatment even for complicated objects involving reflective or black surface; high data completeness and environmental adaptability (deployable in both indoor and outdoor environments). In addition, SCANTECH’s unique mapping technology matches the high-accuracy model obtained using laser scanning with HD photos taken by SLR cameras (5000w pixels), eventually generating high-accuracy color 3D models with clear textures.

3DeVOK 3D color scanner, on the other hand, is more effective in scanning material evidence involving a large plenitude of geometric features and matte textures. No markers are needed and the device is highly portable and easy to operate. High-definition color grains can be obtained to satisfy courts’ need for color data with respect to a part of material evidence.

Statistics show that over the 1-month pilot running period of the material evidence management platform, 5 material evidence warehouses covering a total area of more than 500 square meters have been emptied out in Jiaxing City, releasing over 3,000 pieces of evidence in stock.

Case 2 Footprint analysis

Footprint collection and analysis is one of the major approaches that the police adopt in investigations. Behind an unremarkable footprint may be the information of a suspect’s gender, age, body shape and walking signature.

In traditional footprint extraction, the plaster mold casting method is applied. First, a 2-4 cm high enclosure is first erected around a footprint. Then, plaster slurry is poured from the lower part of the footprint; after the plaster is solidified, the mold is taken out, resined in water and let air dry. The result is a plaster footprint mold.

Such a method entails many drawbacks. It usually takes more than 30 minutes to cast a plaster mold. Once extraction fails, not only cannot footprint mold be obtained, but the footprint information on the scene would be damaged without further remedial possibilities. An abundance of footprint information can often be found on areas of snow, sand and dust. However, it would be extremely difficult to extract footprint on these materials using the plaster casting method.

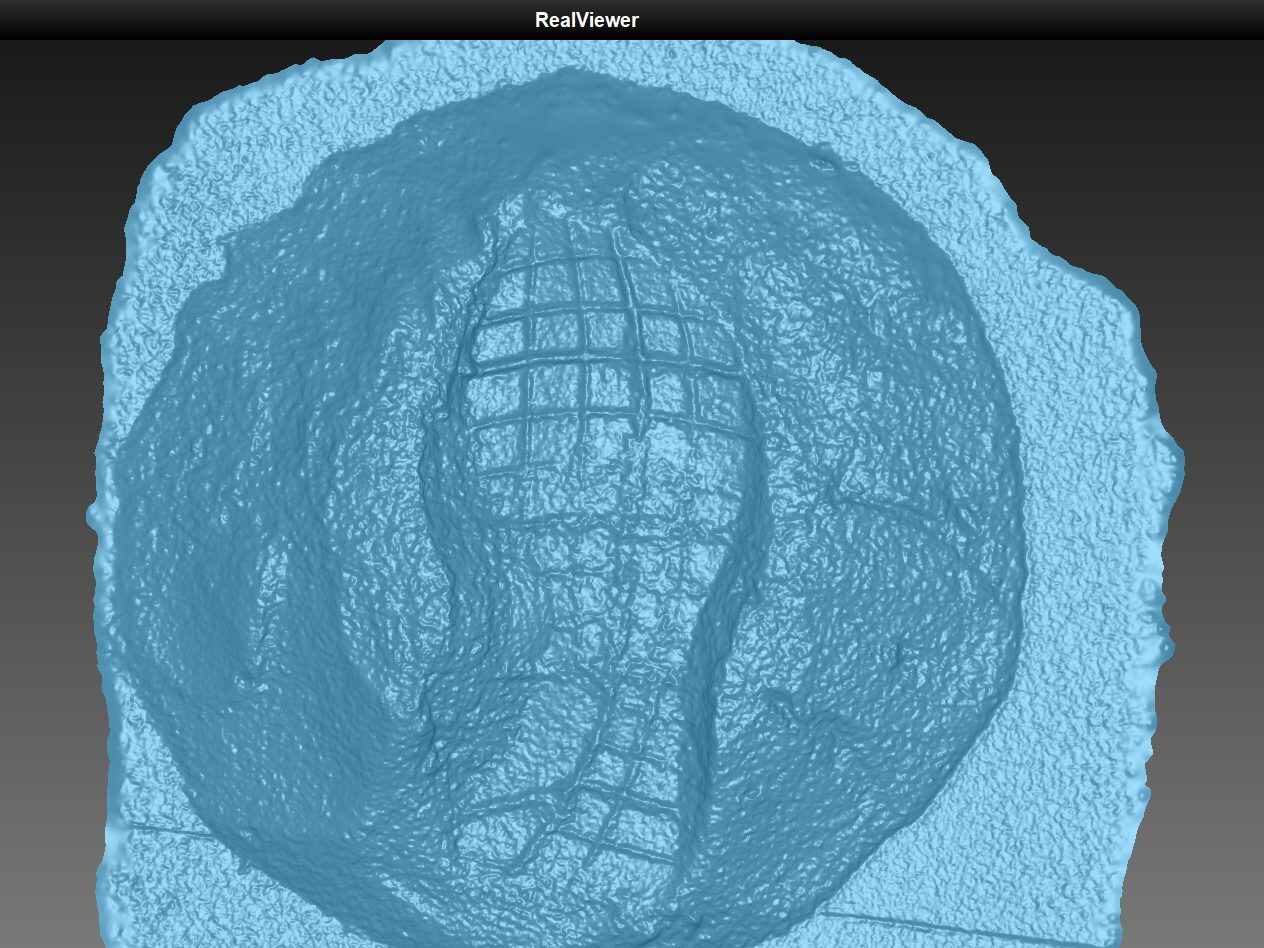

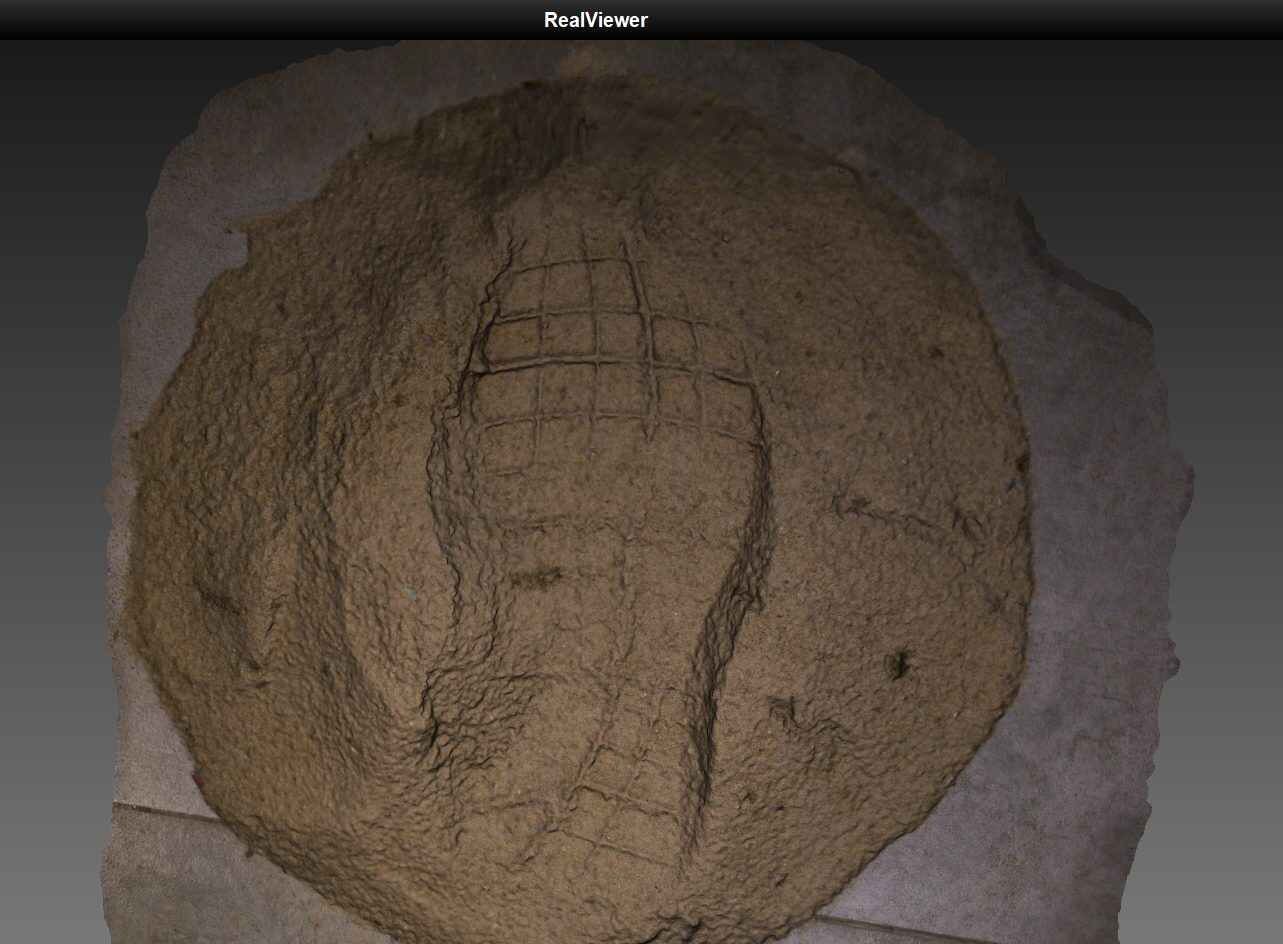

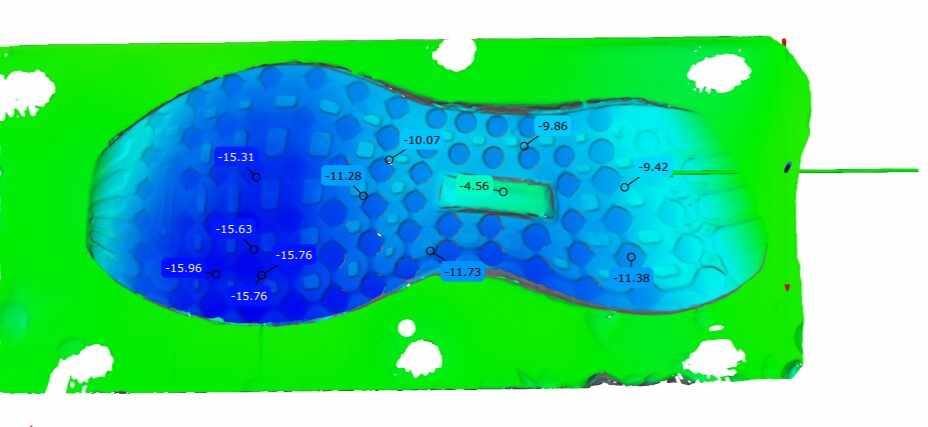

3D scanning provides an entirely new approach to extracting footprints. SCANTECH offers two sets of solutions for footprint extraction: the 3DeVOK texture capturing without markers and the handheld high-accuracy 3D laser scanning solution. Both solutions leave the original morphology of footprints untouched (laser scanners rely on magnetic markers that are attached around a footprint, and thus there is no need to stick markers or physically contact any part of a footprint), and data can be easily obtained even from special materials like snow, sand and dust.

The solution of handheld 3D laser scanning has advantages like high data completeness, accuracy (a maximum accuracy of 0.02mm), and fineness (a maximum fineness of 0.010 mm, thinner than a thread of hair). Even the tiny, narrow grooves on a footprint can be clearly scanned without the slightest error; the solution also has high applicability across various complicated lighting environments (both indoor and outdoor).

The solution of handheld 3D laser scanning has advantages like high data completeness, accuracy (a maximum accuracy of 0.02mm) and fineness (a maximum fineness of 0.010 mm, thinner than a thread of hair). Even the tiny, narrow grooves on a footprint can be clearly scanned without the slightest error; the solution also has high applicability across various complicated lighting environments (both indoor and outdoor).

3D printed model

With the availability of a high-accuracy model, you can print the footprint at the crime scene using a high-precision, industrial 3D printer for evidence preservation and examination, or you can also measure size-related parameters (e.g., the lowest point of the sole or the width of the foot) to assist with determining the sex, age, body shape and walking characteristics of the suspect. Additionally, the model can also be zoomed in and out from different angles for better observation and overlapping comparison, providing more information for investigators.

Footprint 3D data

Case 3 Trauma identification

3D scanning also plays a significant role in trauma identification.

3DeVOK also as a 3D body scanner, is applicable not only to “objects” but also to “humans beings” (for earlier reports on medical scanning of human bodies, you can read the article of Comprehensive 3D Solution for Health Care. In medical care settings, patients’ physical data are needed for diagnosis and treatment; comparatively, trauma data is required in forensic investigations for case discrimination and analysis.

Traditional trauma identification still relies on measuring tapes and photography. However, results obtained by measuring tapes may involve large errors when it comes to irregular traumatic shapes while photos can only deliver 2D images without further information.

3DeVOK color 3D scanner is able to rapidly measure 3D information of a wound like its surface area, circumference and angles that facilitate accurate measurement and evaluation of traumas.

In the meantime, 3DeVOK 3D scanner can also be operated under the invisible light mode to allow a safe and comfortable scanning process that lasts no more than 30 seconds. All these features can effectively increase the efficiency of case investigation and ensure the victim can seek prompt medical care after identification.

All Products

All Products

en

en