Accelerate Reverse Engineering of Pump Impeller Design

With the continuous development of industrialization, water pumping is frequently used in our lives. From civilian water supply and heating water circulation to chemical and pharmaceutical industries, water pumping appears everywhere. The main function of it is to transport water and other types of fluids from one place to another one.

Pump impeller, as a core part of the water pumping, is rotated by the motor to generate mechanical kinetic energy. In manufacturing inspection, the impeller is the main factor that affects the work efficiency of water pumping. Poor pump design makes hydraulic losses and clearance losses at the pump inlet and vanes, affecting kinetic energy.

What manufacturer needs?

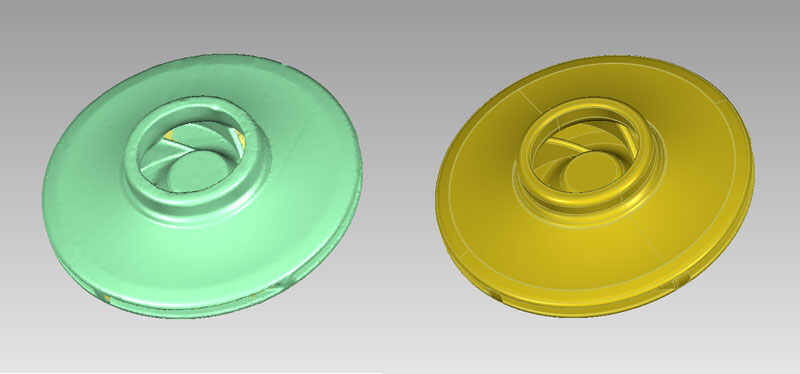

The manufacturer aims to make reverse engineering of the pump impeller, so the premise is how to get the accurate 3D data efficiently. In the past, people used structured 3D scanners to handle this issue, however, this traditional method exists some demerits. Therefore, the manufacturer wants to get the accurate 3D data of pump impeller by portable 3D scanning and depend on 3D software for data processing.

Structured 3D Scanner VS Handheld 3D scanner

Structured 3D Scanner VS Handheld 3D scanner

The pump impeller has a narrow internal structure with many deal angles. How to choose an effective way?

Disadvantages of structured 3D scanner:

- Need power-spray for shiny surface; cause damages to clean the parts

- Complex operation steps cause low-efficiency

- Difficult to get 3D data of interior features and dead angles, which will decrease scanning accuracy and make deviations

Advantages of handheld 3D scanner:

- Powder-spray unrequired

- High flexibility and accuracy to capture 3D data of dead angles and key features

- Fast measurement rate to save labor cost and work time

ScanTech 3D Solution

ScanTech HSCAN handheld 3D scanner meets the manufacturer’s demands in the following aspects:

- Scanning reflective pump impeller without powder-spray

- Accurately and quickly capture 3D data of deep hole and complicated features by 3D scanning

- Portable and flexible scanning allow people or scanner casually to move

- Non-contact measurement avoids any damages

Step 1. Attaching markers on the pump impeller

Step 2. Scanning and getting point cloud data

Step 3. Importing the data into 3D software ScanViewer for data process

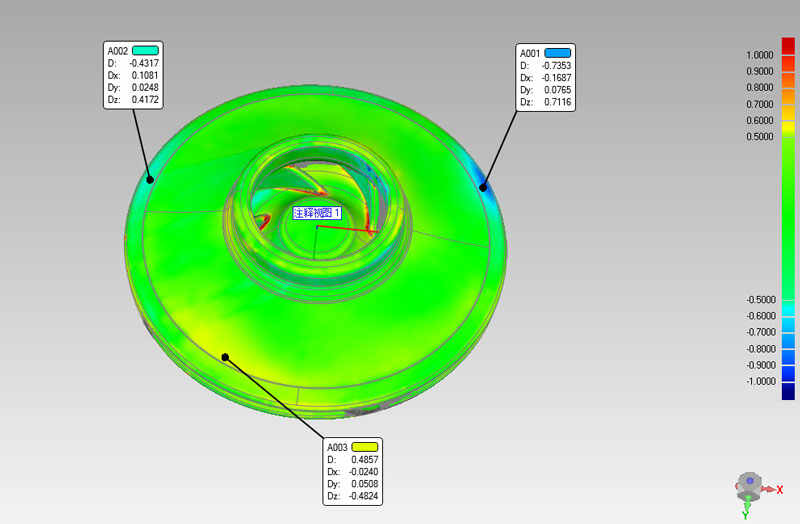

Step 4. Redesign the structure of pump impeller based on inspection deviations

Step 4. Redesign the structure of pump impeller based on inspection deviations

The color map helps engineers clearly know the deviations between the original part and 3D model

It only takes a few minutes to finish the scanning. By using HSCAN 3D scanner, the complete 3D data and realistic 3D model of the pump impeller are easily obtained. This advanced 3D scanning technology optimizes product development and 3D inspection workflows for manufacturing companies.

For more cases about reverse engineering, please read below:

Scientific Research on 3D Scanning of Helicopter

Handheld 3D Scanner – The Trump Card of Electric Bicycle Manufacturers

All Products

All Products

en

en