A leading construction equipment manufacturer in China has recently completed a rapid inspection of mounting holes of excavator chassis by using SCANTECH’s tracking 3D scanning system: TrackScan-P42.

The technician responsible for measuring technologies at the company commented, “It was an eye-opening experience, as it took only 30 minutes to scan the mounting holes with the metrology 3d scanner and generate the analysis report.”

Based in an eastern city of China, the company’s high-quality products have become a trusted name among customers. However, one of the biggest challenges they face is time-consuming inspection. In this case, it is the inspection of mounting holes of an excavator chassis.

Chassis, essential to bear the weight of the whole machine, is usually longer than 3 m, with a complex structure. Tricky areas of the part and inefficient methods amount to a challenging task to obtain mounting holes’ accurate tolerances of shape, form, and position.

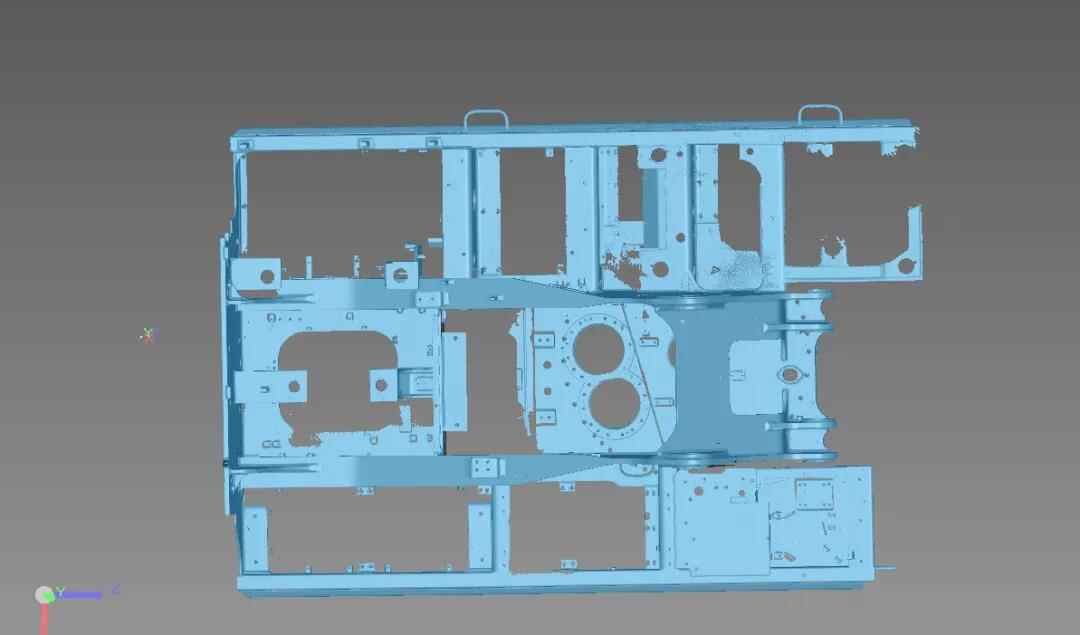

The chassis of an excavator

To ensure optimum quality of inspection, the company contacted SCANTECH to customize a 3D measurement solution that would meet their special requirements.

The manager of the quality assurance department explained how our 3D technology is paving the way for more efficient inspection.

“It is quite demanding to inspect mechanical parts as we have to do it in a laboratory with temperature and humidity controls, and we have to follow complex operating steps. The intuitive workflow provided by SCANTECH helps to make the inspection as easy as taking a video.”

Shop floor inspection

By taking TrackScan-P42 as a core of the 3D inspection solution, engineers from SCANTECH helped to conduct a thorough inspection. Thanks to its intelligent optical tracking measurement technology and high-quality optical equipment, TrackScan-P42 took 3D measurements without markers, and with ultra-high precision.

It captured data at a rate of up to 1.9 million measurements/second. Its deep-hole scanning captured details and hard-to-reach areas in high resolution. When combined with the photogrammetry system MSCAN camera L15, the volumetric accuracy can reach 0.044mm/m+0.015mm/m.

Shop floor inspection

After scanning, all the measuring data were visualized and analyzed with ScanViewer, a software developed in-house by SCANTECH. First, the 3D scan data was cleaned up, aligned, and all unnecessary point clouds were removed.

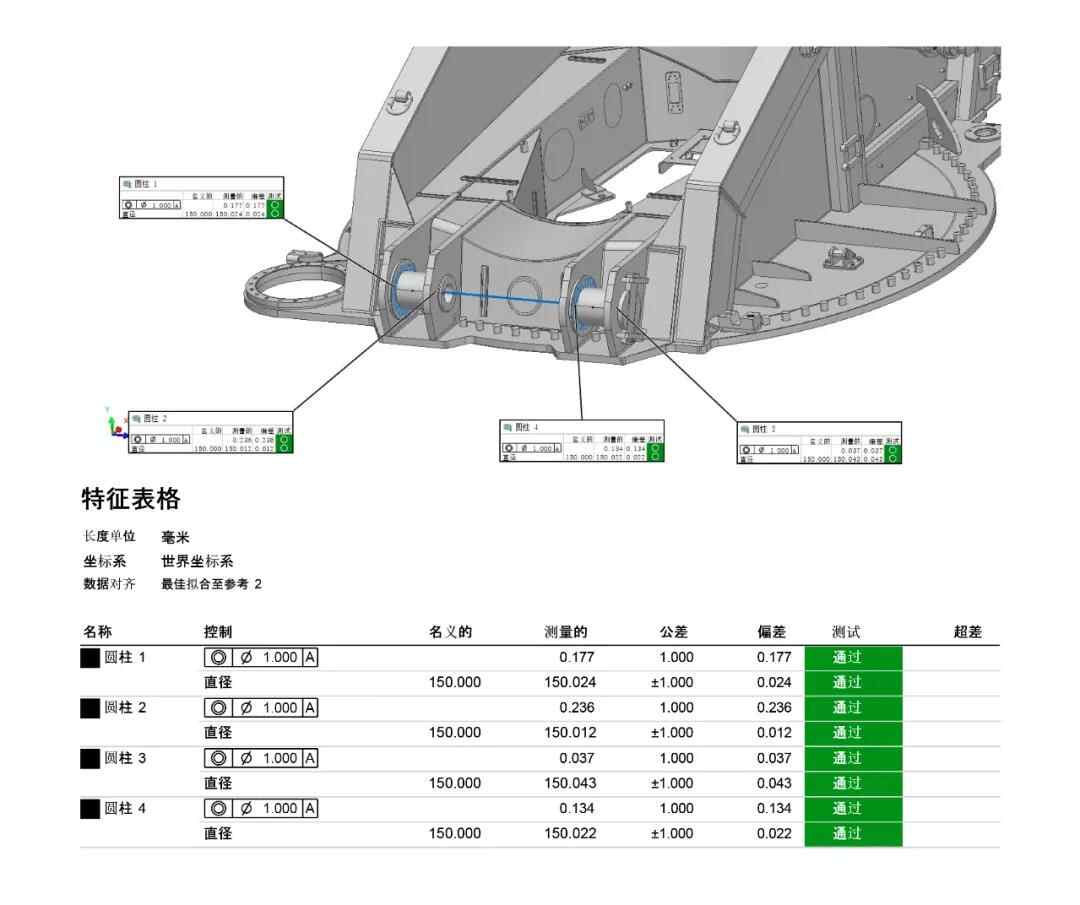

Subsequently, the scan data was compared against CAD. Finally, an analysis report was generated in just a few minutes.

3D scan data

analysis report

Summary

- 3D tracking scanning system TrackScan P-42 was perfectly suited for inspection of large components

- It took 30 minutes to scan and create a report

- A reliable measuring system that ensures precise and consistent results

- Real-time analysis of data saves time and money

Scantech is a high-tech enterprise specialized in developing, manufacturing and selling intelligent visual inspection equipment.

All Products

All Products

en

en