With intelligent optical tracking measurement, TrackScan-P42 3D system delivers instant scanning without markers, greatly improving work efficiency and decreasing cost.

TrackScan-P42 3D System

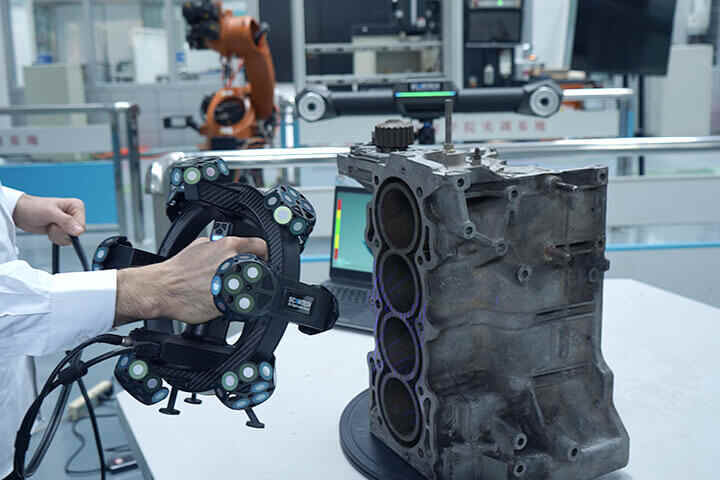

TrackScan-P42 3D system adopts intelligent optical tracking measurement technology and high-quality optical equipment. It carries out ultra-high precision dynamic 3D measurement without markers. This 3D system is widely applied to quality control, product development, reverse engineering, etc.

By freely switching between multiple working modes, TrackScan-P42 caters to different scanning situations. Three scanning modes enable a variety of scene scans.

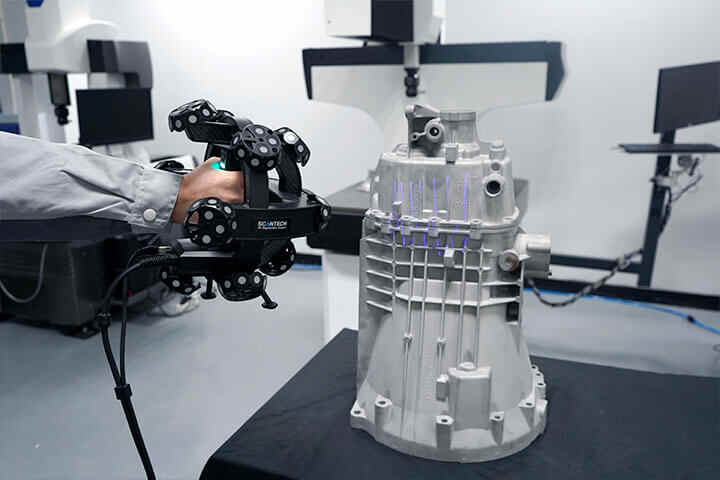

This optical 3D scanner can be paired with wireless portable CMM to conduct flexible measurements and deliver high-precision 3D data. Gaps, holes, grooves and complex surface are no longer a challenge for manufacturers and engineers. TrackScan-P series of optical 3D scanner can also be mounted onto a robot-arm to realize intelligent and automated 3D inspection.

With 17 blue laser crosses and an ultra-fast scanning rate of up to 1,900,000 measurements/s, this 3D optical cmm laser scanner enables smooth 3D scanning experiences. Its 7 parallel blue laser lines work well for detail capturing. Single blue laser line aims to fast obtain 3D data of deep holes and dead angle positions.

Easily capture 3D data for shiny and black surface, strong anti-interference capability of environment, vibrations and thermal variations.

Portable CMM is designed for getting precise 3D data of holes and hidden points, with high single point repeatability of 0.030 mm.

Ready To Get Started?

Rebuild our 3D world with the most advanced 3D scanning system available.

Technical Specifications

Technical specification

| Type | TrackScan-P42 | ||

| Scan mode | Ultra-fast scanning | 17 blue laser crosses | |

| Hyperfine mode B | 7 blue parallel laser lines | ||

| Deep hole scanning | 1 extra blue laser line | ||

| Laser lines in total | 42 | ||

| Accuracy(1) | Up to 0.025 mm | ||

| Measurement rate | Up to 1,900,000 measurements/s | ||

| Scanning area | Up to 500 mm × 600 mm | ||

| Laser class | ClassⅡ (eye-safe) | ||

| Resolution | 0.020 mm | ||

| Volumetric accuracy(2) | 10.4 m³ | 0.064 mm | |

| 18.0 m³ | 0.078 mm | ||

| Volumetric accuracy (With MSCAN-L15 photogrammetry system ) |

0.044 mm + 0.015 mm/m | ||

| Portable CMM | Optional | Support | |

| Single point repeatability | 0.030 mm | ||

| Part size range (recommended) | 200 ~ 6000 mm | ||

| Stand-off distance | 300 mm | ||

| Depth of field | 400 mm | ||

| Output formats | .stl, .ply, .obj, .igs, wrl, .xyz, .dae, .fbx, .ma, .asc or customized | ||

| Operating temperature range | -10 °C ~ 40 °C | ||

| Interface mode | USB 3.0 | ||

| Patents | CN204329903U, CN104501740B, CN104165600B, CN204988183U, CN204854633U, CN204944431U, CN204902788U, CN105068384B, CN105049664B, CN204902784U, CN204963812U, CN204902785U, CN204902790U, CN106403845B, CN209197685U, CN209263911U, CN106500627B, CN106500628B, CN206132003U, CN211121096U, US10309770B2, KR102096806B1 | ||

(1) ISO 17025 accredited: Based on VDI/VDE 2634 Part 3 standard and JJF 1951 specification, probing error (size) (PS) performance is evaluated.

(2) ISO 17025 accredited: Based on VDI/VDE 2634 Part3 standard and JJF 1951 specification, sphere spacing error (SD) performance is evaluated.

All Products

All Products

en

en